Precise instruments for experimentation, powerful tools for productivity

Abbess Vacuum Chambers provide the foundation for a broad range of systems, serving uses from scientific experimentation to industrial production. Abbess’s vertically integrated engineering sales, design and fabrication method positions the company to respond to stock order and custom fabrication requirements promptly and cost effectively.

Component and Package leak testing, degassing, vacuum process methods, altitude flight and deep space simulations; Abbess Vacuum Chambers serve as powerful and well crafted tools in countless sciences and industries. .

Round/Tube Vacuum Chambers

Digital VCC Controlled Low Vacuum Chamber

Digitally Controlled Low Vacuum Chamber for use in a variety of applications, including degassing

Scalable Industrial Degassing of compounds/substances in 55-gallon batches. Degassing and mixing of liquids under vacuum improves product quality and increases the efficiency of degassing and impregnating of substances.

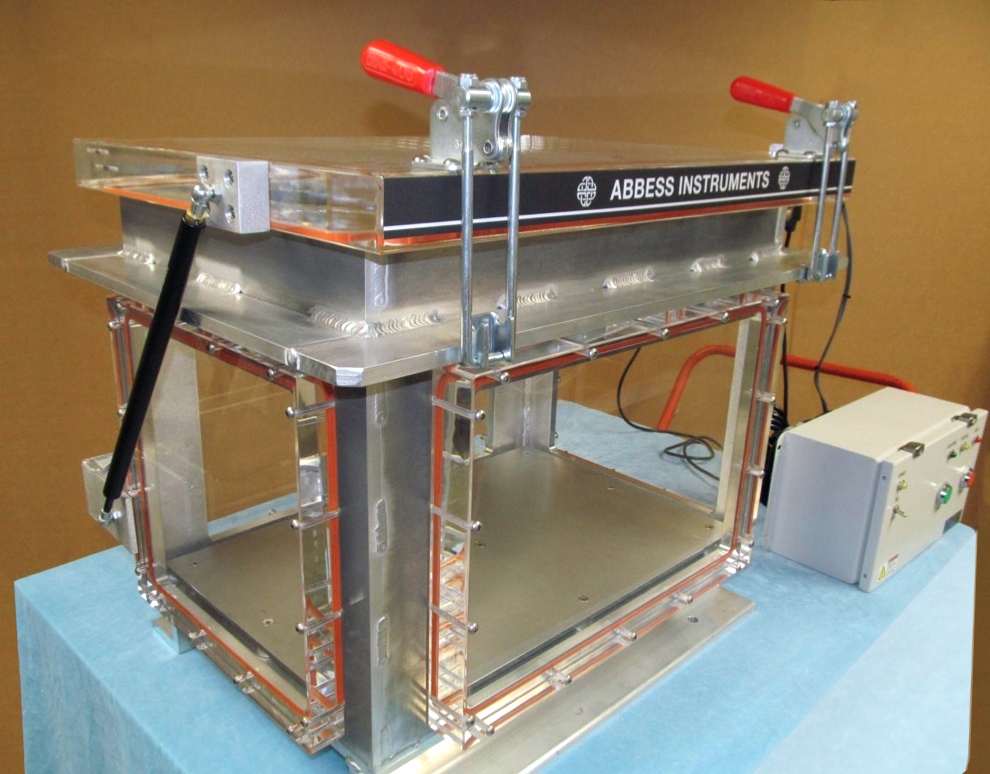

Vacuum Pressing and Sealing in a Vacuum Chamber

Allows you to apply tons of force in a vacuum chamber.

VE-11 Vacuum Chamber, Liquid Filling

Vacuum Liquid Filling (like inks), Encapsulation, Impregnation, Degassing Systems

Economy 5-Gallon Bucket, with Mixer

We designed a standard 5-gallon vacuum chamber mixing unit to streamline the ordering process. Mixing can greatly improve the degassing operation of almost all materials; it is a must for thicker materials like pastes and gels.

This bench top sized vacuum chamber is designed to be a rugged production or testing unit. Some of our customers find this to be a practical size for use in vacuum degassing small batches of resins, epoxies,other liquids, or filling molds and other containers under vacuum.

Vacuum Chamber for Degassing and Mixing on a Cart

11 inch or 15 inch diameter by 6,12, 20, 24, 36 inch deep vacuum chamber with hose, vacuum pump, fittings, valves, and gauge

Custom Round Chambers and Systems

Some of our customers find this vacuum chamber to be a practical size and shape for use in vacuum degassing liquids and soilds, EMI and altitude testing electronics, research, and development.

Production Grade Degassing System

11 inch or 15 inch diameter by 6,12 or 20 inch deep vacuum chamber with hose, vacuum pump, fittings, valves, and gauge.

Bell Jar Replacement, Vacuum Chamber, No Glass

A heavy Acrylic vacuum chamber on a metal base plate, 11 inch, 15 inch, 24 diameters by 6,12 or 20 inch high

This chamber is used for vacuum drying samples and other material processing where temperature and time are critical.

High Vacuum Acrylic Bell Chamber

This Thermal Vacuum Chamber System allows items placed inside to be contained in a high vacuum environment to facilitate customer process production requirements . The entire thermal vacuum chamber system can be controlled manually, by starting/stopping the pump(s) and opening/closing valves.

Square or Cube Vacuum Chambers

PTFE Non-Stick Coated Vacuum Chambers

These vacuum chambers are designed to be rugged production or testing units for each customers' unique requirements.

Vacuum Mixing & Casting System with PC Based Controller

Complete with vacuum regulation and motor Start/stop contactor

Thermal Vacuum Gas Mix Test Chamber

The Abbess Thermal Vacuum Custom Gas Mix System allows articles under test placed inside the chamber to be exposed to high vacuum pressure as well as various temperatures via a heated and cooled Main Thermal Plate Assembly.

Vacuum Degassing and Oil Fill System

This double-chambered, semi-automated vacuum system allows for degas and Fill processing. (Thumbnail shown with analog VCC)

Large Scale Vacuum Systems, Custom

A custom-designed vacuum system configured to top-load large scale parts into a solution for cleansing/dring/degassing.

These vacuum chambers are in-stock chambers ready for immediate shipment. Next day service available.

These Vacuum Oven Systems are designed and built to be rugged and efficient systems for use in production or testing.

Large Vacuum Storage Systems, Modular

Vacuum Storage System Custom configured to your requirements. complete systems with Pumps, controllers and other options

Top Loading Vacuum Chambers, for Transport in Vacuum or Low Pressure Gas Cover

Doors open on the top of the vacuum chamber. Allows the user to work with a top loading format, place and remove objects in a vertical axis of motion.

Vacuum Oven Systems—Custom configured to your requirements. Complete systems with pumps, controllers and other options

Top and Side Loading Vacuum Chamber with Turntable

Doors open on the top and side of the camber. Windows look onto a rotating turntable within the chamber. LED lights illuminate the interior.

This custom high vacuum chamber with thermal inserts is capable of being used as a large-scale space simulation/thermal vacuum chamber.

This Dual Altitude Chamber System has two separate chambers that function and are controlled independently. This system a facilitates the user to conduct and monitor separate or parallel tests.

High Vacuum System with Thermal Shroud

This 48 inch cube system (thermal vacuum chamber) allows items placed inside to be exposed to vacuum down to 10^-7 Torr. A Vacuum Cycle Controller (VCC) is used to automate control functions.

High Vacuum – Thermal Vacuum System

The Abbess Thermal Vacuum Chamber System shown allows Article(s) Under Test placed inside to be exposed to high vacuum (10e-8 range) as well as heated and cooled via conductive contact with the Gold Plated Copper Thermal Plate.

Process Passage/In-Line Vacuum Chamber

This in-line vacuum chamber allows an assembly line to go through this vacuum chamber by way of a two-door entry points.

Clear Acrylic Cube Vacuum Chamber

This bench top sized vacuum chamber is designed to be a rugged unit with 1-1/2" thick walls and true o-ring seals for deep vacuums and long life.

Each vacuum chamber with thermal plates can be built to customer requirements (thermal vacuum chamber)

Overview of Vacuum Oven Systems

Dry in our manual or automatic, data-logged or not, single or multi-chambered, Vacuum Oven systems.

24 Inch Cube, Standard Vacuum Chamber

Our standard vacuum chamber is a 24 inch Cube, 24" high x 24" deep x 24" wide, a practical production size for use in vacuum degassing of liquids, plastics resins, and epoxies.

High Vacuum Chambers

10-5 to 10-9 Torr

Aeronautic Component Test System

This vacuum chamber system is configured as a versatile platform to conduct aeronautic component tests with. With a temperature range of +200C to -96C, this system is ideal for robust test procedures in both industrial and academic laboratories.

Achieve dry, and controlled conditions for your items and batches with our process-versatile, multi-access, multi-functional, with a optional automated chamber controller and data logger.

Thermal Vacuum Gas Mix Test Chamber

The Abbess Thermal Vacuum Custom Gas Mix System allows articles under test placed inside the chamber to be exposed to high vacuum pressure as well as various temperatures via a heated and cooled Main Thermal Plate Assembly.

Achieve dry, and controlled conditions for your items and batches with our process-versatile, multi-access, multi-functional, with a optional automated chamber controller and data logger.

This custom high vacuum chamber with thermal inserts is capable of being used as a large-scale space simulation/thermal vacuum chamber.

Automated Space Simulation System with -80C Cascade Refrigeration

This system allows articles under test placed inside to be exposed to high vacuum pressure as well as various temperatures via the heated and cooled Thermal Plate Assembly. A Thermal Vacuum Cycle Controller (TVCC) is used to automate and control functions.

High Vacuum System with Thermal Shroud

This 48 inch cube system (thermal vacuum chamber) allows items placed inside to be exposed to vacuum down to 10^-7 Torr. A Vacuum Cycle Controller (VCC) is used to automate control functions.

High Vacuum – Thermal Vacuum System

The Abbess Thermal Vacuum Chamber System shown allows Article(s) Under Test placed inside to be exposed to high vacuum (10e-8 range) as well as heated and cooled via conductive contact with the Gold Plated Copper Thermal Plate.

High Vacuum Acrylic Bell Chamber

This Thermal Vacuum Chamber System allows items placed inside to be contained in a high vacuum environment to facilitate customer process production requirements . The entire thermal vacuum chamber system can be controlled manually, by starting/stopping the pump(s) and opening/closing valves.

Replicate atmospheric conditions within the vacuum chamber system. This vacuum chamber sytem is ideal for space simulation testing. 6 heated and cooled thermal plates.

Thermal Vacuum Chambers

Thermal components can be integrated into any system in the temperature range of (cold)-320F/-196C to (Hot)+300F/150C with vacuum from atmosphere to 10-9 torr.

Satellite Testing Vacuum System

Satellite Testing Vacuum Systems engineered and built for the satellite industry. These systems can be customized for your desired test procedure. The inner Thermal Shroud can be coated with AeroGlaze® to further improve your testing environment.

Thermal Vacuum Solar Simulation System

Abbess Thermal Vacuum and Solar Simulation Chamber Systems are designed and produced for use in laboratory production and testing applications requiring an exposure to or process within a controlled vacuum environment at specific temperature involving solar simulation.

Thermal Vacuum Gas Mix Test Chamber

The Abbess Thermal Vacuum Custom Gas Mix System allows articles under test placed inside the chamber to be exposed to high vacuum pressure as well as various temperatures via a heated and cooled Main Thermal Plate Assembly.

Multi-Plate Thermal Vacuum Chambers

Multi-plate thermal vacuum systems are built to customer specifications, testing requirements, and budget.

These Vacuum Oven Systems are designed and built to be rugged and efficient systems for use in production or testing.

Vacuum Oven Systems—Custom configured to your requirements. Complete systems with pumps, controllers and other options

This custom high vacuum chamber with thermal inserts is capable of being used as a large-scale space simulation/thermal vacuum chamber.

The Abbess Thermal Vacuum Chamber System shown facilitates thermal and vacuum profiles consistent with altitudes to 200K feet. Â Customer defined devices are supported with an array of 25 pin D-sub, BNC and SMA feedthrus.

Automated Space Simulation System with -80C Cascade Refrigeration

This system allows articles under test placed inside to be exposed to high vacuum pressure as well as various temperatures via the heated and cooled Thermal Plate Assembly. A Thermal Vacuum Cycle Controller (TVCC) is used to automate and control functions.

High Vacuum System with Thermal Shroud

This 48 inch cube system (thermal vacuum chamber) allows items placed inside to be exposed to vacuum down to 10^-7 Torr. A Vacuum Cycle Controller (VCC) is used to automate control functions.

Abbess offers fully custom designed and engineered  systems in order to meet customer specification. The system allows articles under test placed inside to be exposed to high vacuum pressure as well as various temperatures via the heated and cooled Thermal Plate Assembly (thermal vacuum chamber).

High Vacuum – Thermal Vacuum System

The Abbess Thermal Vacuum Chamber System shown allows Article(s) Under Test placed inside to be exposed to high vacuum (10e-8 range) as well as heated and cooled via conductive contact with the Gold Plated Copper Thermal Plate.

Multimode Cooling, Thermal Vacuum Chamber System

The Abbess Multimode Thermal Vacuum Chamber System serves as the flexible platform for a range of thermal vacuum testing and experimentation methods. Multimode is cooling using 2 different methods.

Each vacuum chamber with thermal plates can be built to customer requirements (thermal vacuum chamber)

Replicate atmospheric conditions within the vacuum chamber system. This vacuum chamber sytem is ideal for space simulation testing. 6 heated and cooled thermal plates.

Overview of Vacuum Oven Systems

Dry in our manual or automatic, data-logged or not, single or multi-chambered, Vacuum Oven systems.

Low Vacuum – Thermal Vacuum System

The Thermal Vacuum System allows items placed inside of the thermal vacuum chamber to be exposed to vacuum as well as heat or cooled via the Thermal Plate.

Altitude and Atmosphere Testing Systems

Temperature range (cold)-112F/-80C to (Hot)+300F/150C and Altitudes up to 100,000 feet

Altitude Testing Chamber for Product Transit Testing

Altitude Chambers full integrable into your vibration of shaker tables to provide a robust transit testing platform for your product.

Aeronautic Component Test System

This vacuum chamber system is configured as a versatile platform to conduct aeronautic component tests with. With a temperature range of +200C to -96C, this system is ideal for robust test procedures in both industrial and academic laboratories.

Satellite Testing Vacuum System

Satellite Testing Vacuum Systems engineered and built for the satellite industry. These systems can be customized for your desired test procedure. The inner Thermal Shroud can be coated with AeroGlaze® to further improve your testing environment.

High Altitude Testing Vacuum Chamber

This Vacuum System allows items placed inside to be exposed to specific vacuum levels and rates of change. A Vacuum Cycle Controller (VCC) is used to automate control functions. The VCC enables system monitoring and control via touch screen buttons and graphic indications of sensor data registered and controlled by a PC with a user-specific Graphical User Interface (GUI).

The tall size of the altitude chamber allows sample carts to be wheeled in with ease. By being able to load the chamber efficiently, it is easier to subject the product sample process to various altitudes. The operable clear acrylic port provides quick and easy access to a test system without needing to unclamp the larger door.

24 inch Pressure/Vacuum Chamber

This 24 inch cube is capable of process testing in both vacuum and positive pressure.

This Dual Altitude Chamber System has two separate chambers that function and are controlled independently. This system a facilitates the user to conduct and monitor separate or parallel tests.

The Abbess Thermal Vacuum Chamber System shown facilitates thermal and vacuum profiles consistent with altitudes to 200K feet. Â Customer defined devices are supported with an array of 25 pin D-sub, BNC and SMA feedthrus.

Custom Round Chambers and Systems

Some of our customers find this vacuum chamber to be a practical size and shape for use in vacuum degassing liquids and soilds, EMI and altitude testing electronics, research, and development.

High Vacuum – Thermal Vacuum System

The Abbess Thermal Vacuum Chamber System shown allows Article(s) Under Test placed inside to be exposed to high vacuum (10e-8 range) as well as heated and cooled via conductive contact with the Gold Plated Copper Thermal Plate.

Replicate atmospheric conditions within the vacuum chamber system. This vacuum chamber sytem is ideal for space simulation testing. 6 heated and cooled thermal plates.

Space Simulation Systems and Chambers

Temperature range (cold)-320F/-196C to (Hot)+300F/150C and from controlled atmosphere to 10-9 torr

Satellite Testing Vacuum System

Satellite Testing Vacuum Systems engineered and built for the satellite industry. These systems can be customized for your desired test procedure. The inner Thermal Shroud can be coated with AeroGlaze® to further improve your testing environment.

Thermal Vacuum Solar Simulation System

Abbess Thermal Vacuum and Solar Simulation Chamber Systems are designed and produced for use in laboratory production and testing applications requiring an exposure to or process within a controlled vacuum environment at specific temperature involving solar simulation.

Multi-Plate Thermal Vacuum Chambers

Multi-plate thermal vacuum systems are built to customer specifications, testing requirements, and budget.

This custom high vacuum chamber with thermal inserts is capable of being used as a large-scale space simulation/thermal vacuum chamber.

Automated Space Simulation System with -80C Cascade Refrigeration

This system allows articles under test placed inside to be exposed to high vacuum pressure as well as various temperatures via the heated and cooled Thermal Plate Assembly. A Thermal Vacuum Cycle Controller (TVCC) is used to automate and control functions.

High Vacuum System with Thermal Shroud

This 48 inch cube system (thermal vacuum chamber) allows items placed inside to be exposed to vacuum down to 10^-7 Torr. A Vacuum Cycle Controller (VCC) is used to automate control functions.

High Vacuum – Thermal Vacuum System

The Abbess Thermal Vacuum Chamber System shown allows Article(s) Under Test placed inside to be exposed to high vacuum (10e-8 range) as well as heated and cooled via conductive contact with the Gold Plated Copper Thermal Plate.

Multimode Cooling, Thermal Vacuum Chamber System

The Abbess Multimode Thermal Vacuum Chamber System serves as the flexible platform for a range of thermal vacuum testing and experimentation methods. Multimode is cooling using 2 different methods.

Replicate atmospheric conditions within the vacuum chamber system. This vacuum chamber sytem is ideal for space simulation testing. 6 heated and cooled thermal plates.

Vacuum Controllers and Automation

Aeronautic Component Test System

This vacuum chamber system is configured as a versatile platform to conduct aeronautic component tests with. With a temperature range of +200C to -96C, this system is ideal for robust test procedures in both industrial and academic laboratories.

Basic Vacuum Sequencer and Cycle Timer with Vacuum Regulator

Abbess Vacuum Cycle Controller (VCC)—This Controller is designed to be a part of our rugged bench top vacuum chambers in production or testing. Some of our customers find this to be a practical solution for using a vacuum chamber in a controlled process to dry products, and degas of parts, liquids, plastics, resins, and epoxies.

This system will produce a very high quality vacuum bag heatseal in a high vacuum.

Vacuum Infusing and Impregnating System

Vacuum infusing, Vacuum impregnating, and Vacuum filling can greatly improve the Product Quality of 3D printed items.

Vacuum Mixing & Casting System with PC Based Controller

Complete with vacuum regulation and motor Start/stop contactor

Achieve dry, and controlled conditions for your items and batches with our process-versatile, multi-access, multi-functional, with a optional automated chamber controller and data logger.

Vacuum Degassing and Oil Fill System

This double-chambered, semi-automated vacuum system allows for degas and Fill processing. (Thumbnail shown with analog VCC)

Robotic Vacuum Dispensing Chamber with Touch Screen Controller

Robotic interface allows custom and percise automation under vacuum

These Vacuum Oven Systems are designed and built to be rugged and efficient systems for use in production or testing.

Large Vacuum Storage Systems, Modular

Vacuum Storage System Custom configured to your requirements. complete systems with Pumps, controllers and other options

Vacuum Oven Systems—Custom configured to your requirements. Complete systems with pumps, controllers and other options

Top and Side Loading Vacuum Chamber with Turntable

Doors open on the top and side of the camber. Windows look onto a rotating turntable within the chamber. LED lights illuminate the interior.

VE-11 Vacuum Chamber, Liquid Filling

Vacuum Liquid Filling (like inks), Encapsulation, Impregnation, Degassing Systems

The tall size of the altitude chamber allows sample carts to be wheeled in with ease. By being able to load the chamber efficiently, it is easier to subject the product sample process to various altitudes. The operable clear acrylic port provides quick and easy access to a test system without needing to unclamp the larger door.

This custom high vacuum chamber with thermal inserts is capable of being used as a large-scale space simulation/thermal vacuum chamber.

Automated Space Simulation System with -80C Cascade Refrigeration

This system allows articles under test placed inside to be exposed to high vacuum pressure as well as various temperatures via the heated and cooled Thermal Plate Assembly. A Thermal Vacuum Cycle Controller (TVCC) is used to automate and control functions.

Each vacuum chamber with thermal plates can be built to customer requirements (thermal vacuum chamber)

Low Vacuum – Thermal Vacuum System

The Thermal Vacuum System allows items placed inside of the thermal vacuum chamber to be exposed to vacuum as well as heat or cooled via the Thermal Plate.

VE-14 and VE-18 Inch Cubes, Vacuum Dispensing

Vacuum Encapsulation, Impregnation, Degassing System Custom configured to your requirements. 14 and 18 inch cubes complete systems with Rotary, Pouring, liquid Despensing controls, Heat, Rotary Tables and other options

Degassing Kits

These vacuum chambers are in-stock chambers ready for immediate shipment. Next day service available.

This bench top sized vacuum chamber is designed to be a rugged production or testing unit. Some of our customers find this to be a practical size for use in vacuum degassing small batches of resins, epoxies,other liquids, or filling molds and other containers under vacuum.

Low Cost – Complete Vacuum Desiccator or Degassing Chamber Kits

2 sizes of vacuum chambers with hose, vacuum pump, fittings, valve, and gauge

Vacuum Chamber for Degassing and Mixing on a Cart

11 inch or 15 inch diameter by 6,12, 20, 24, 36 inch deep vacuum chamber with hose, vacuum pump, fittings, valves, and gauge

Production Grade Degassing System

11 inch or 15 inch diameter by 6,12 or 20 inch deep vacuum chamber with hose, vacuum pump, fittings, valves, and gauge.

High Vacuum Acrylic Bell Chamber

This Thermal Vacuum Chamber System allows items placed inside to be contained in a high vacuum environment to facilitate customer process production requirements . The entire thermal vacuum chamber system can be controlled manually, by starting/stopping the pump(s) and opening/closing valves.

Overview of Vacuum Oven Systems

Dry in our manual or automatic, data-logged or not, single or multi-chambered, Vacuum Oven systems.

24 Inch Cube, Standard Vacuum Chamber

Our standard vacuum chamber is a 24 inch Cube, 24" high x 24" deep x 24" wide, a practical production size for use in vacuum degassing of liquids, plastics resins, and epoxies.

Vacuum Pumps and Accessories

One-Handed Door Latch Assembly

This vacuum chamber latching assembly enables easy access and maneuvering with one-hand.

Thermal Vacuum Solar Simulation System

Abbess Thermal Vacuum and Solar Simulation Chamber Systems are designed and produced for use in laboratory production and testing applications requiring an exposure to or process within a controlled vacuum environment at specific temperature involving solar simulation.

Abbess can help you press and/or seal your medical, pharmaceutical, food, electronics, and aerospace packaging under vacuum using either seal bar(s) or seal plate(s).

A wobble stick allows movement within a vacuum chamber. Most movements that would typically be done by hand can be done through a wobble stick. For example, in a vacuum under pressure, a wobble stick can move to press a button or rotate an object.

High Density, High Count, Thermocouple Port

High Density, High Count, Thermocouple Port

UHV/HV Manual Vent to Atmosphere Kit

For manual tempered venting of UHV/HV systems.

Manual LV Vent to Gas Purge Kit Automated LV Vent to Gas Purge Kit Manual UHV/HV Vent to Gas Purge Kit Automated UHV/HV Vent to Gas Purge Kit

Pfeiffer Model HiPace 400 Turbo Molecular Pump with TC400 Integrated Controller

Pfeiffer Model HiPace 400 Turbo Molecular Pump with TC400 Integrated Controller

Pfeiffer Model HiPace 80 Turbo Molecular Pump with TC110 Integrated Controller

Pfeiffer Model HiPace 80 Turbo Molecular pump with TC110 Integrated Controller

Pfeiffer Model HiPace 700 Turbo Molecular Pump with TC400 Integrated Controller

Pfeiffer Model HiPace 700 Turbo Molecular Pump with TC400 Integrated Controller

Pfeiffer Model HiPace 1200 Turbo Molecular Pump with TC1200 Integrated Controller

Pfeiffer Model HiPace 1200 Turbo Molecular Pump with TC1200 Integrated Controller

Vacuum hose sizes are determined by the system's pump, size, and capacity.

SMI Filters for vacuum service

An insertion shaft runs through an airlock that allows for powders, liquids and other substances to be added to the vacuum chamber without breaking the vacuum.

Abbess Vacuum Gauge Selection Page

Product selection guide to help you find the best gauge for your outfit

Vacuum Pump Exhaust and Inlet Filters

General: For peak output performance from a compressor, blower, vacuum pump, engine, or any other machine that consumes air, one must have clean, unrestricted air.

Turn tables allow customers to rotate a number of products under a dispensing point (please see our liquid feed-thrus) under vacuum conditions.

PTFE Non-Stick Coated Vacuum Chambers

These vacuum chambers are designed to be rugged production or testing units for each customers' unique requirements.

Rotary and Linear motion – Vacuum Feed-Thru

Provides rotary connection into a vacuum chamber for mixing, pouring, turning, separating, sealing, closeing or handling materials in vacuum.

Take a look at the different window options

Coaxial or Tri-axial Vacuum Feed-Thru

For electrical connections to samples mounted in vacuum and other applications, BNC, SMA, and others.

Vacuum Pumps and Systems for use with vacuum chambers.

Basic Vacuum Sequencer and Cycle Timer with Vacuum Regulator

Abbess Vacuum Cycle Controller (VCC)—This Controller is designed to be a part of our rugged bench top vacuum chambers in production or testing. Some of our customers find this to be a practical solution for using a vacuum chamber in a controlled process to dry products, and degas of parts, liquids, plastics, resins, and epoxies.

The Contamination Control Package will be of greatest interest to our Space Simulation customers, especially those who will be placing actual Space Flight hardware in our chambers – whether in component, subsystem, or full system form.

Compact Oil Mist Exhaust Filters ~ SMI Filters for vacuum service ~ "EF" Series 1/2" - 1 3/4" MPT & Fine Thread

Vacuum Filters for Water and Odor

Whats your vacuum problem: Water? Odor? Both? We can help solve both problems in the vacuum space.