Vacuum Conversion Factors

From Inches of Hg

to Atmospheres multiply by 0.0334211

to Bars multiply by 0.0338639

to mm of Hg multiply by 25.4 (Torrs=1mmHg)

to Grams/sq. cm multiply by 34.5316

to pounds/sq. ft multiply by 70.7262

From Atmospheres

to Bars multiply by 1.01325

to mm of Hg multiply by 760

to Grams/sq. cm multiply by 1033.23

to Pounds/sq. inch multiply by 14.6960

to Torrs multiply by 760

to Ft of H2O multiply by 33.8995

References and Data Sheets for Applications:

Cast Acrylic Properties

Better known by name brands such as Plexiglass, Acrylite, Chemcast, Methacrylates, etc. Acrylic plastic offers durability and is an excellent substitute for glass, acetate, polycarbonate or PVC when one is looking for transparency or translucency. It is half the weight of glass and 45% the weight of aluminum. Maximum Service Temperature, Air 65 – 112 °C 149 – 234 °F Average = 94.5 °C; Transmission, Visible 92%.

- Cast Acrylic Properties – General Material Data Sheet

- Cast Acrylic Properties – Physical Properties and Chemical Resistance Data sheet (pdf)

Specifying Degassing Vacuum and Temperature

Use these tools to help figure out what vacuum and temperature you should be specifying for your vacuum process:

Boiling Point Calculators

- (low vacuum) https://www.sigmaaldrich.com/chemistry/solvents/learning-center/nomograph.html

- https://www-jmg.ch.cam.ac.uk/tools/magnus/boil.html

Energy Conversion Tool https://www.colby.edu/chemistry/PChem/Hartree.html

Database of Properties of Common Laboratory Solvents

- https://organicdivision.org/organic_solvents.html

- https://www2.onu.edu/~b-myers/organic_solvents.html

Note that our most basic chambers are designed for 10-4 Torr operation. Refer to Table 1: Chamber Material Choices for more detail. In reality, the designed operational pressure will be adversely affected by, if nothing else, outgassing of customer’s product (and inadequate cleaning and preconditioning), and the customer should specify accordingly. Pumps should be chosen with ultimate pressures an order of magnitude better than the desired process pressure. Refer to our pump page for the ultimate pressure of available pumps (our most economical pumps are specified at 25 mTorr, whereas 10-4 Torr is the lowest rated pump without going to a Turbo system).

O-Ring Material Options

| Material |

Recommended Use |

Not Recommended For |

Mechanical Properties |

| Buna-N (Nitrile) Standard: 70 Durometer Black Temperature Range: -35 ºF to 250 ºF Least Expensive / Readily Available |

Silicone Greases / Oils Water Petroleum Oils / Fuels Ethylene Glycol Fluids |

Ketones (MEK) Halogenated Hydrocarbons Auto / Aircraft Brake Fluids Strong Acids Sunlight, Ozone, Weathering |

Good Wear Resistance Good Compression Set Resistance Good Short-Term Resilience Good Permeation Resistance |

| Viton ® (Fluorocarbon Type A) Standard: 75 Durometer Black Temperature Range: -15 ºF to 400 ºF |

Vacuum Most Acids / Chemicals Halogenated Hydrocarbons Di-Ester Lubricants Petroleum Oils / Fuels Silicone Oils / Greases |

Ketones (MEK) Auto / Aircraft Brake Fluids Amines (Ammonia) Acetone, Skydrol, Ethyl Acetate Hot Water and Steam Low Molecular Esters and Ethers |

Good Wear Resistance Excellent Comp. Set Resistance Moderate Short-Term Resilience Excellent Permeation Resistance |

| Silicone Standard: 70 Durometer Orange Temperature Range: -65 ºF to 450 ºF |

Dry Heat Wide Temperature Range Sunlight, Ozone, Weathering Odorless and Non-Toxic |

Ketones (MEK) Acids Silicone Oils Brake Fluids |

Poor Wear Resistance Excellent Comp. Set Resistance Poor Short-Term Resilience Excellent Permeation Resistance |

| EPDM (Ethylene Propylene) Standard: 70 Durometer Black Temperature Range: -60 ºF to 250 ºF |

Sunlight, Ozone, Weathering Hot Water and Steam Auto / Aircraft Brake Fluids Some Acids and Bases Ketones and Alcohols Plumbing |

Petroleum Oils Fuels |

Good Wear Resistance Good Comp. Set Resistance Moderate Short-Term Resilience Good Permeation Resistance |

| Chemraz ® / Kalrez ® / Simriz ® (Perfluoroelastomer) Various Compounds Designed for Specific Applications Temperature Range: -10 ºF to 615 ºF |

High Temperature Resistance Excellent Chemical Resistance Low Out Gassing Chlorine Wet/Dry Petroleum Oil Chlorinated Hydrocarbons |

Molten metals Gaseous Alkali Metals Halogenated Freons/Fluids Uranium Hexafluoride |

Good Wear Resistance Good Comp. Set Resistance Moderate Short-Term Resilience Good Permeation Resistance |

| Material |

Recommended Use |

Not Recommended For |

Mechanical Properties |

| Neoprene ® (Chloroprene) Standard: 70 Durometer Black Temperature Range: -35 ºF to 250 ºF |

Refrigerants (Freon) Ammonia Some Petroleum Oils Dilute Acids Silicone ester Lubricants |

Ketones (MEK) Gasoline Auto / Aircraft Brake Fluids |

Good Wear Resistance Moderate Comp. Set Resistance Moderate Short-Term Resilience Good Permeation Resistance |

| Urethane Standard: 90 Durometer Translucent Temperature Range: -65 ºF to 200 ºF |

Drive Belts Some Petroleum Oils Some Hydrocarbon Fuels Oxygen / Ozone |

Ketones (MEK) Acids Auto / Aircraft Brake Fluids Chlorinated Hydrocarbons Water |

Excellent Wear Resistance Poor Comp. Set Resistance Excellent Short-Term Resilience |

| Fluorosilicone Standard: 70 Durometer Blue Temperature Range: -80 ºF to 450 ºF |

Jet Fuel Dry Heat Wide Temperature Range Some Petroleum Oils Chlorinated Solvents |

Ketones (MEK) Phosphate Esters Some Acids Auto / Aircraft Brake Fluids Amines (Ammonia) |

Poor Wear Resistance Moderate Comp. Set Resistance Moderate Short-Term Resilience Poor Permeation Resistance |

| PTFE non-stick coating encapsulated O-Ring Covered with PTFE non-stick coating Tube Usually Silicone or Viton ® |

Depends on O-Ring Core Chemical Resistance Heat Resistance |

Depends on O-Ring Core | Good Wear Resistance Good Short-Term Resilience Good Permeation Resistance |

| PTFE non-stick coating Standard: Non-Elastic White Temperature Range: -250 ºF to 450 ºF |

Chemical Resistance Fuel Resistance Low Coefficient of Friction |

Non-Elastic | Good Wear Resistance Low Coefficient of Friction |

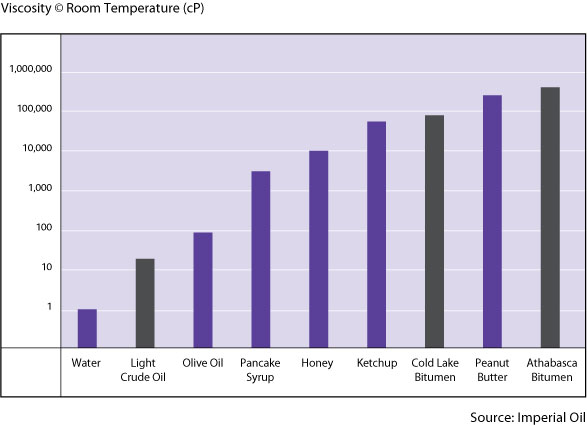

Source: https://www.centreflow.ca/2009/10/26/laying-it-on-thick/ and Imperial Oil