Getter Cold Finger Overview

Abbess Instruments’ Cold Fingers are designed to augment HV and UHV vacuum chamber environments. Cold Fingers work to improve the overall Pumpdowns in vacuum chambers in both speed of Pumpdown as well as the ultimate vacuum level for the systems they are placed in. These elements are used to act as the cold element within the vacuum chamber and attract condensable volatiles within the environment. By attracting these condensable vapors to the cold finger, the overall pumping capacity of the vacuum system can be improved.

- Includes:

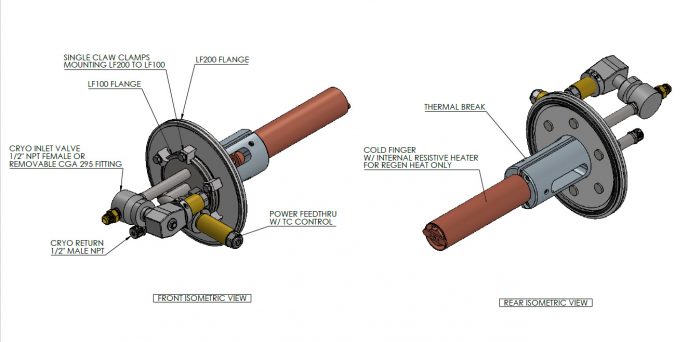

- Cold Finger for –196°C operation, with bare copper sleeve or molecular sieve sleeve (see photo below)

- Mounted on a 4″ or greater ISO flange

- 1/2″ JIC SS braided Cooling supply Lines

- Cryogenic Connectors

- Assembly and Test

- Temperature controller (i.e. Type K)

- Thermocouple

- Optional Upgrades:

- Supply transfer Lines

- Custom Sleeves

- Regenerative Heater option

- Required Items:

- LN2 Supply (or chiller)

- Thermocouple readout

- Mating chamber flange

This device is meant to act as the coldest element within a vacuum chamber to augment the pumping system. Doing so will allow users to attract condensable vapors to the getter sleeve and improve overall pumping capacity of their vacuum systems. The sieve holding sleeves are removable from the assembly to allow selective gettering of condensable vapors to adapt to your current applications.

Abbess Cold fingers can be adapted to any project. From a bakeout chamber that goes up to +200°C to a thermal vacuum chamber that goes down to –196°C.

Cold Finger Connections

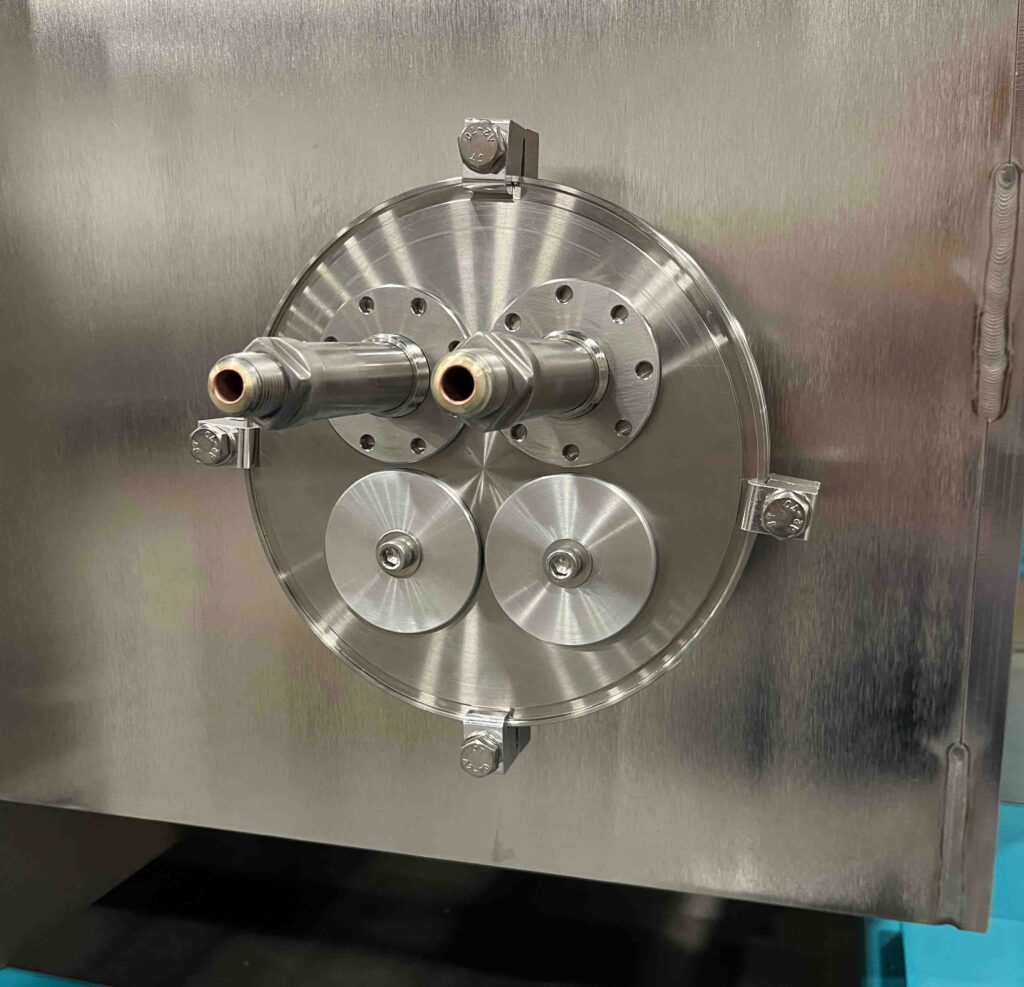

Shown below is the view of the LF200 flange mounted to the exterior of the chamber. Along with the supply and return lines for the cooling source.

Here you can see the Cold Fingers physical presences in the interior of the shroud. While Abbess’ Cold Finger is not a cryopump it acts as a getter in even a large chamber making it an excellent cost-effective option in addition to a dry roughing pump. The product is designed and produced for use in production and testing applications requiring an exposure to or process within a controlled vacuum environment at specific temperature.

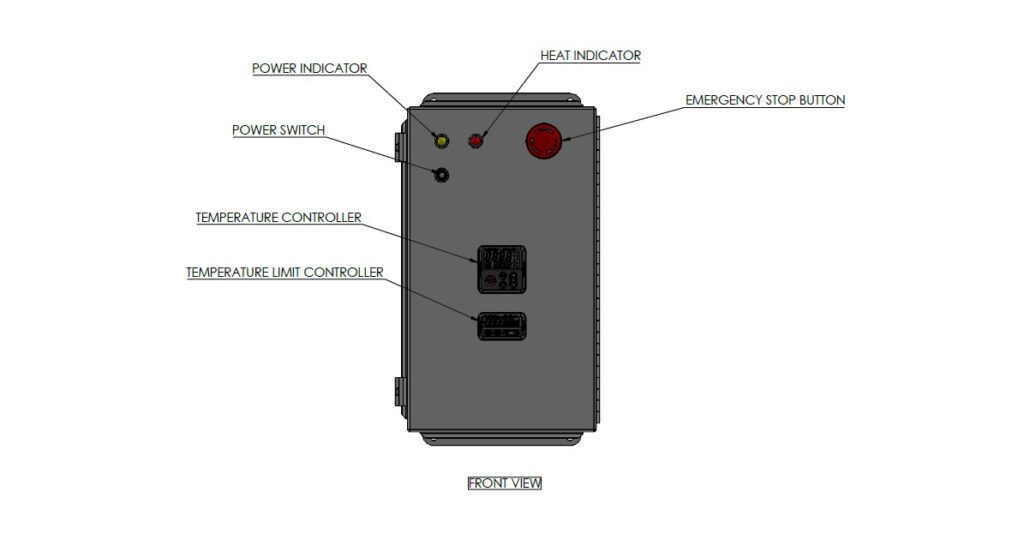

Cold Finger Controls

- NEMA Control Enclosure (Unless already Integrated into System)

- Watlow EZ-Zone PM Controller for Cryogenic valve control as well as regenerative heating via insertion heater mounted inside the cold finger

- E-Stop in the event of emergency

- LED Indicators

- Main Power Switch

- Cryogenic On/Off Valve

- Allows flow of cryogenic medium through the assembly

Drawings of all Components:

To get an accurate quote for the system you need fill out our RFQ or call today!