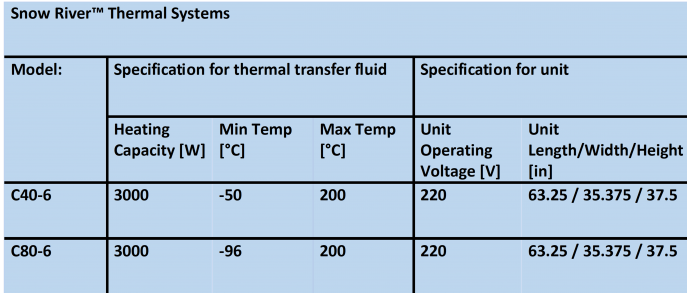

The Snow River® C40-6 Cascade Chiller is the most versatile closed loop cooling and heating system offered by Abbess®. This system is a single stage refrigeration system that offers precise control from -50C to +200C. The Snow River® Thermal Systems can be configured to incorporate most thermal load or process including those offered by Abbess such as a thermal plate, finned heat exchanger or a recirculating thermal fluid.

The Snow River® Thermal Systems can be configured to incorporate most thermal load or process including those offered by Abbess.

Our C40-6 single-stage cascade chiller can be used for:

- Thermal vacuum chambers

- Satellite testing (space simulation)

- Cold Traps

- Environmental test chambers (with altitude, temperature, and humidity control)

- Ultra-low temperature freezers

- Lyophilizes (freeze dryers)

- Lasers, NMRs, Liquid chromatography–mass spectrometers, cold traps, and other devices

- Cryogenic storage

- Bio storage (bio refrigeration)

- DNA storage (sample preservation)

- Forensic samples

- Genetic sample storage (animal, plant, archaeological)

Snow River® Dimensions

Dimensions:

Total Depth: 75.16 inches (1,909 mm)

Total Height: 37.46 inches / 31.84 inches with Casters removed (951.48 mm / 808.74 mm)

Total Width: 35.12 inches (892.05 mm)

Estimated Gross Weight: 1,500 lbs (682 kg)

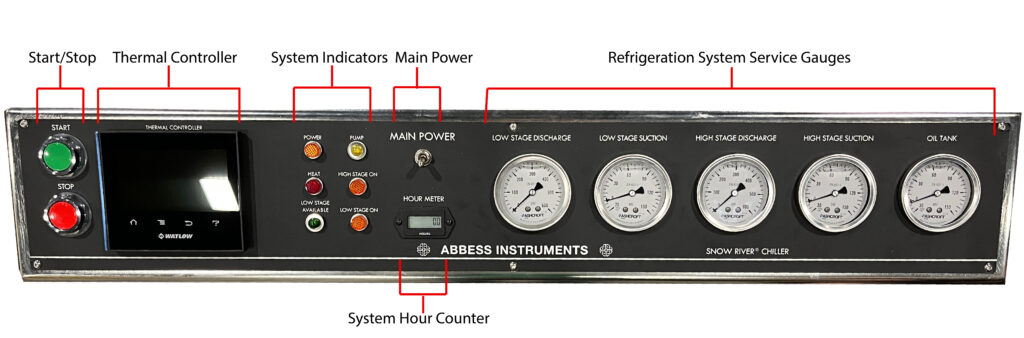

Snow River® Control Panel

Snow River® Theory of Operation

The Snow River® cascade chiller contains a 20 gallon tank filled with Syltherm-XLT fluid or another fluid upon request that is used for thermal transfer. The refrigeration consists of one loop: a high stage with 404a refrigerant. When cooling the high stage (404a) runs continuously to cool the Syltherm tank that cools the thermal load. This allows the thermal transfer fluid passing through its evaporator to -50C. The thermal transfer fluid is constantly run through a refrigerated heat exchanger and is in contact with a heater located within the tank. The oil is blanketed with low-pressure 30 PSI of dry nitrogen to ensure that no air or no moisture condenses or freezes within the closed oil loop. This is also done for the health and safety of the tank to avoid any corrosion. The refrigeration compressors and heater are managed by the chiller’s PID controller on the front panel to achieve oil temperature set points between -50C and +200C. After exiting the refrigerated heat exchanger, a 3-way ball valve is used to direct thermal transfer fluid either directly back to its holding tank or out to the thermal process. This ball valve can be controlled by an analog 4-20mA signal. This signal could come from a PLC, process PID controller, or control PC interface.

The thermal transfer fluid within the chiller can be either pre-cooled before the test in recirculation mode (ball valve closed) for quick cool-downs or can be cooled while circulating through a thermal load or process for more gradual cooling processes. In cases where the thermal transfer fluid is pre-cooled, an analog signal from an exterior source or onboard process PID controller remains low (4mA) until the desired bath temperature is reached. This low analog signal keeps the 3-way ball valve in the system “closed” and directs thermal transfer fluid directly back to the bath after exiting the refrigerated heat exchanger. This quickly cools the thermal fluid in the bath. Once the desired bath temperature is reached, the analog signal can be increased up to 20mA to “open” the three-way valve and allow fluid to flow out of the system to a chamber’s thermal plate, shroud or to another custom process. The three-way ball valve can be opened partially, and its response to the analog input is proportional, so a 4-20mA signal will open the ball valve halfway.

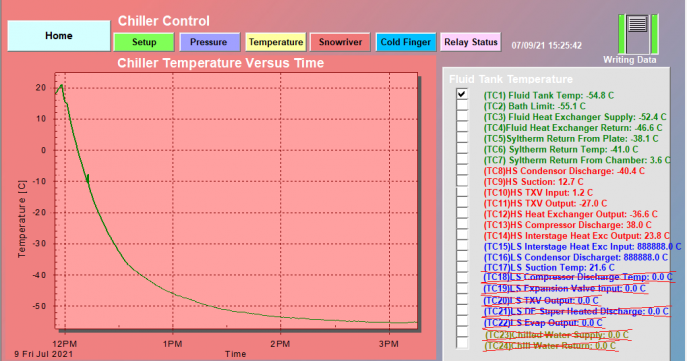

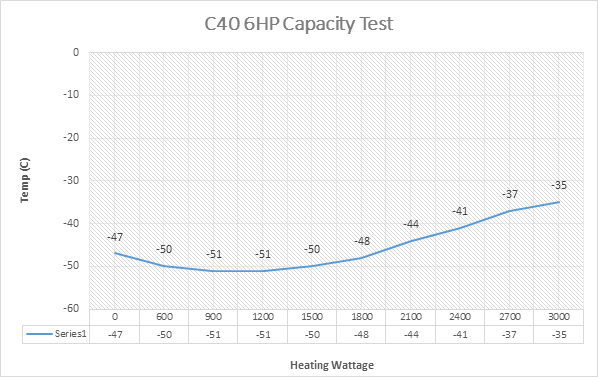

Snow River® C40-6HP Expected Performance

Figure 2: Shows the expected cool down rate of a C40-6HP chiller with no thermal load (the cool down and rates will vary with a test article). The cool down rate to -45 °C is about 1 hour.

Figure 3: Shows the C40-6HP chiller with a thermal load over time of varying wattages (the cool down and rates will vary with a test article). With the C40-6HP chiller can withstand a 3,000 W load at -35 °C.

Features of Standard Chiller Systems

- PID temperature controllers offer precise thermal control and profiling. These controllers provide stand alone setpoint control and profiling capability or can be networked using RS-485 to be monitored and manipulated from an Abbess or customer designed PC interface.

- Programmable sealed bath temperature range: -50C to +200C

- Modular cooling units provide scalable cooling capacity that minimizes the need for field service with simple on-site unit replacement and installs.

- Systems are replaced and installed in just a matter of minutes with no loss of fluid!

- Cost-effective solution for reliable, stable and precise thermal control systems

- Eliminates high running cost associated with liquid nitrogen used in open loop cryo cooling and freon used in large-scale refrigeration systems. These systems provide a significantly improved return on investment compared to other ultra-low temperature cooling systems.

- Controllable bath temperature provides for a better temperature gradient across load at steady state temperatures. Reduced cold spots that are experienced with liquid nitrogen cooling.

- Independent thermal load and bath control allows for fast and precise temperature control

Optional Features of Chiller Systems

- Flexible Control Interface Options

- Touchscreen PC control for complete control and monitoring of a single or of multiple Snow River® cascade chiller systems.

- System capable of monitor each Snow River® thermal systems temperature, pressure, faults and other conditions. (Self-diagnostic capabilities)

- Allow for the PC controller to make appropriate system changes to correct deviation from operational parameters.

- Systems with multiple Snow River® cascade chiller systems have a recruitment function that can recruit and/or deactivate system modules as needed.

- Secure remote capabilities facilitate monitoring and operations

- Advanced thermal profiling control

To get an accurate quote for the system you need fill out our RFQ or call today!