Mixing Under Vacuum to Improve Sample Quality

Mixing can greatly improve the degassing operation of almost all materials; it is a must for thicker materials like pastes and gels. With Abbess Instruments can help you to prevent the integration of air into your product by using a vacuum mixer. Vacuum mixing chambers can be used for a wide variety of material including, but not limited to: foods, herbs, papers, liquids, jells, powders, plastics resins, epoxies and many other parts and materials. The in-vacuum capability allows a large quantity of material to be mixed and degassed for enhanced performance.

Whether you are mixing in a 5-gallon drum or a 55-gallon drum, we have mixers in a range of sizes. The power options range from manual hand rotary mixers to fully automated horsepower level mixers. We will work with you to assess what mixing system your material requires.

To get an accurate quote for a system-specific for your needs, or to get help from our engineers, fill out our RFQ or call today!

Featured Products:

Industrial Mixing of epoxy, jells, or liquids under vacuum - no need to degas, no air to form bubbles

Scalable Industrial Degassing of compounds/substances in 55-gallon batches. Degassing and mixing of liquids under vacuum improves product quality and increases the efficiency of degassing and impregnating of substances.

Vacuum Mixing & Casting System with PC Based Controller

Complete with vacuum regulation and motor Start/stop contactor

Vacuum Degassing and Oil Fill System

This double-chambered, semi-automated vacuum system allows for degas and Fill processing. (Thumbnail shown with analog VCC)

Large Scale Vacuum Systems, Custom

A custom-designed vacuum system configured to top-load large scale parts into a solution for cleansing/dring/degassing.

These vacuum chambers are in-stock chambers ready for immediate shipment. Next day service available.

Economy 5-Gallon Bucket, with Mixer

We designed a standard 5-gallon vacuum chamber mixing unit to streamline the ordering process. Mixing can greatly improve the degassing operation of almost all materials; it is a must for thicker materials like pastes and gels.

This bench top sized vacuum chamber is designed to be a rugged production or testing unit. Some of our customers find this to be a practical size for use in vacuum degassing small batches of resins, epoxies,other liquids, or filling molds and other containers under vacuum.

Vacuum Chamber for Degassing and Mixing on a Cart

11 inch or 15 inch diameter by 6,12, 20, 24, 36 inch deep vacuum chamber with hose, vacuum pump, fittings, valves, and gauge

Production Grade Degassing System

11 inch or 15 inch diameter by 6,12 or 20 inch deep vacuum chamber with hose, vacuum pump, fittings, valves, and gauge.

Bell Jar Replacement, Vacuum Chamber, No Glass

A heavy Acrylic vacuum chamber on a metal base plate, 11 inch, 15 inch, 24 diameters by 6,12 or 20 inch high

Electric Mixer 5 gallon design and Vacuum Casting mixer

These Chambers are constructed of heavy alloy. Our customers find this to be a practical size for use in vacuum degassing and vacuum processing of all sorts of items including, but not limited to: foods, herbs, papers, liquids, jells, powders, plastics resins, epoxies and many other parts and materials. This chamber is also used in many industries where vacuum work is required

In vacuum heaters can be ordered with your chamber (round top loading chambers only).

All chambers are vacuum tested to 29.92 inches of Hg or better (10-6 torr ) and should maintain this for its life dependent on seal condition and customer use.

Hand mixer in a 11″ x 12″ Economy (degassing water) and 11″x 6″ Economy chamber

| Vacuum: | Down to 29.92″ Hg under dynamic vacuum Need a Vacuum Pump? See our Vacuum pump |

| Component: | |

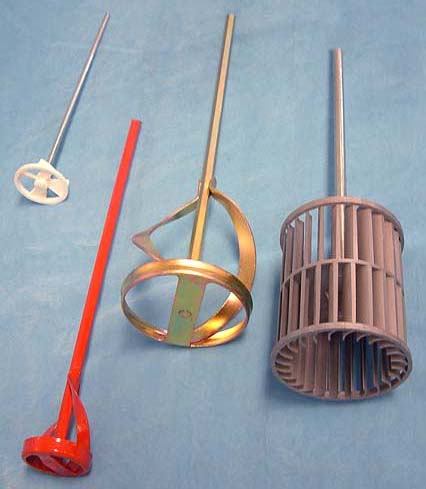

| Included Features: |  (from left to right) mini blade for 3/8″ , 1 gallon blade for 1/2″ , 5 gallon blade for 1/2″, other “squirrel cage” blade |

Vacuum Rotary Feedthru and Coupling (from top to bottom) 3/8″ , 1/2″ , 3/4″ | |

| Optional Features/Items: |

Mixer Blades and attachments

|

Use the following guidelines to select the right mixer for your needs:

|

To mix a material then fill a product, both under vacuum, see our Multi-Chamber Systems.

To fill a product with a mixed material, see our Filling Systems.