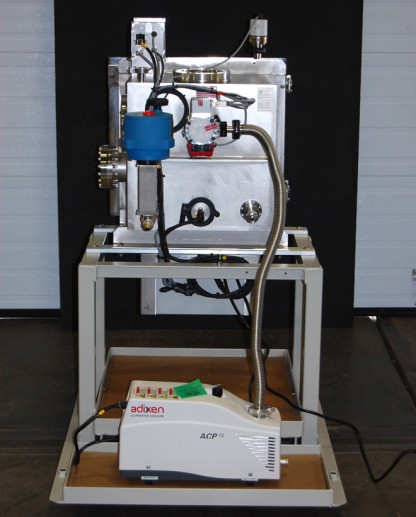

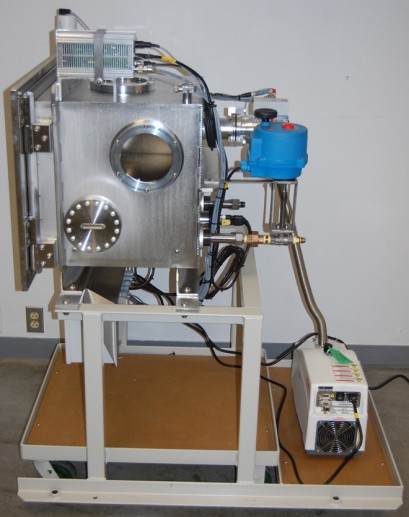

The Abbess Thermal Vacuum Chamber System shown allows Article(s) Under Test placed inside to be exposed to high vacuum (10e-8 range) as well as heated and cooled via conductive contact with the Gold Plated Copper Thermal Plate. Customer defined process is supported with a 50 pin D-sub High Vacuum CF feedthru and UV Grade Quartz view portals. Thermal and Vacuum controls are addressed as discrete concerns with toggle switch power to actuate the vacuum pumping system (Pfeiffer HiPace 80 Turbo Pump and Alcatel/Adixen ACP 15 Backing Pump) and PID ramping control of the thermal plate system (via temperature controller). The system stands alone on a mobile custom steel frame caster cart. Facility support requirements include power to the pumping system and heat cartridge elements of the thermal plate and LN2 Dewar to support the cooling loop.

This Vacuum System consists of the following major components:

- Vacuum Chamber – Front Loading Stainless Steel Cube, Electropolished to facilitate high vacuum level performance.

- Thermal Plate – Gold plated Copper Thermal Platen mounted in the bottom of chamber with cartridge heating elements and cooling loop (for connection to facility supplied LN2). Feed-through for electrical power, thermocouple and cooling lines extend through the rear wall of the chamber.

- Controlled by PID temperature Controller mounted in Process Control Enclosure.

- Mobile Cart – Heavy-duty cart/stand with chamber and pumping system mounted and tested ready to use.

- Vacuum Gauge and Controller integrated with on board Turbo Control of Pfeiffer HiPace

- Manual Vent Valve – Manual override vent valve to allow chamber to atmosphere at end of cycle.