Satellite Testing Vacuum Systems engineered and built for the satellite industry.

With precise thermal and vacuum control, the Abbess Satellite Testing Vacuum System is ideal for ensuring the compliance and ability of your product or satellite to sustain ultra-high and low atmosphere conditions. Abbess designs rugged equipment and practical systems for continuous and demanding analytical, manufacturing, and production use, with safety and long life in mind. Additionally, we offer various coating for solar simulation and other orbital variables.

Chambers are helium leak tested to a rate of 10e-7 cc/sec or better as required by the end user needs, and are designed to maintain this level for extended robust use dependent on seal condition and customer practice.

To get an accurate quote for the system you need fill out our RFQ or call today!

Satellite Testing Vacuum System Features:

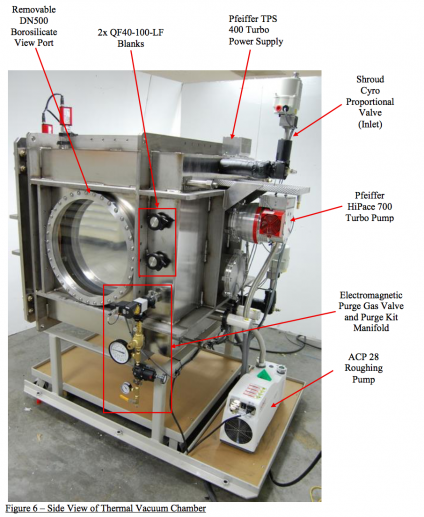

- Vacuum Chamber (as shown above) – A Front Loading 36” x 36” x 36” Stainless Steel Chamber with a right hinged Stainless Steel door. The interior of the chamber is Electropolished to attain high vacuum.

- Vacuum Pumping System

- Thermal Platen System – AeroGlaze® Coated Aluminum Thermal Plate with resistance cartridge heating elements and refrigeration media piping engaged in the under the surface of the thermal test platen.

- Thermal Shroud System – 5 sided AeroGlaze® coated Aluminum thermal plate with resistance cartridge heating elements and refrigeration media piping embeded in the back of each shroud. Thermocouple monitoring and temperature control via PID controller.

- Pressure Gauges/Pressure Transducers

- Control Valves

- Electromechanical Foreline Valve – Seperates the chamber and Turbo from the Roughing pump when venting the Chamber.

- Electromechanical Chamber Vent Valve – Gross venting valve.

- Electromechanical Chamber Purge Gas Vent Valve – Connected to the gas purge kit to allow dry nitrogen purge into the chamber.

- Gas Purge Kit – A set of preconfigured regulators, pressure relief valve, and gauges provide a controlled release of gas into the chamber.

Perform your test in-house for decades to come with this modifiable and upgradeable Satellite Testing Vacuum System:

Benefits:

- Highly developed altitude simulation and data collection touch screen system

- Custom user interface that is configured to custom specified equipment on your system including thermal controls

- Plot and save data, settings, and profiles

- Precise and reliable control of altitude up to 200,000ft

- Editable PID configuration with auto-tuning capabilities

- Ramp rate control (in ft/min) for climb and dive simulation

- Practically unlimited step profiles