Abbess’s Thermal Shrouds allow for reliable and uniform cooling/heating under vacuum.

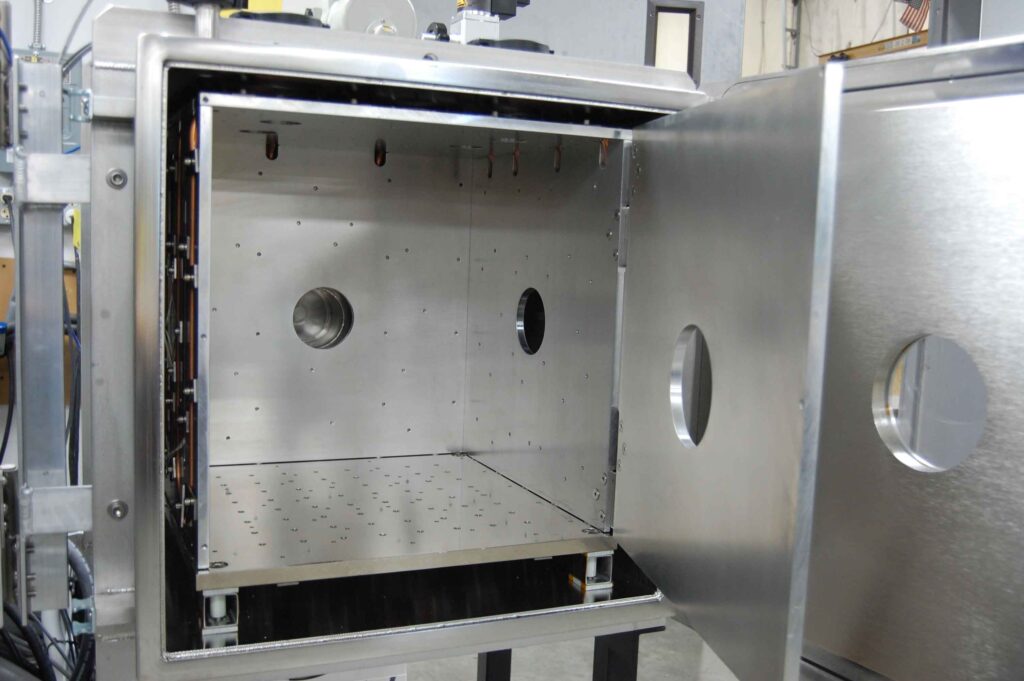

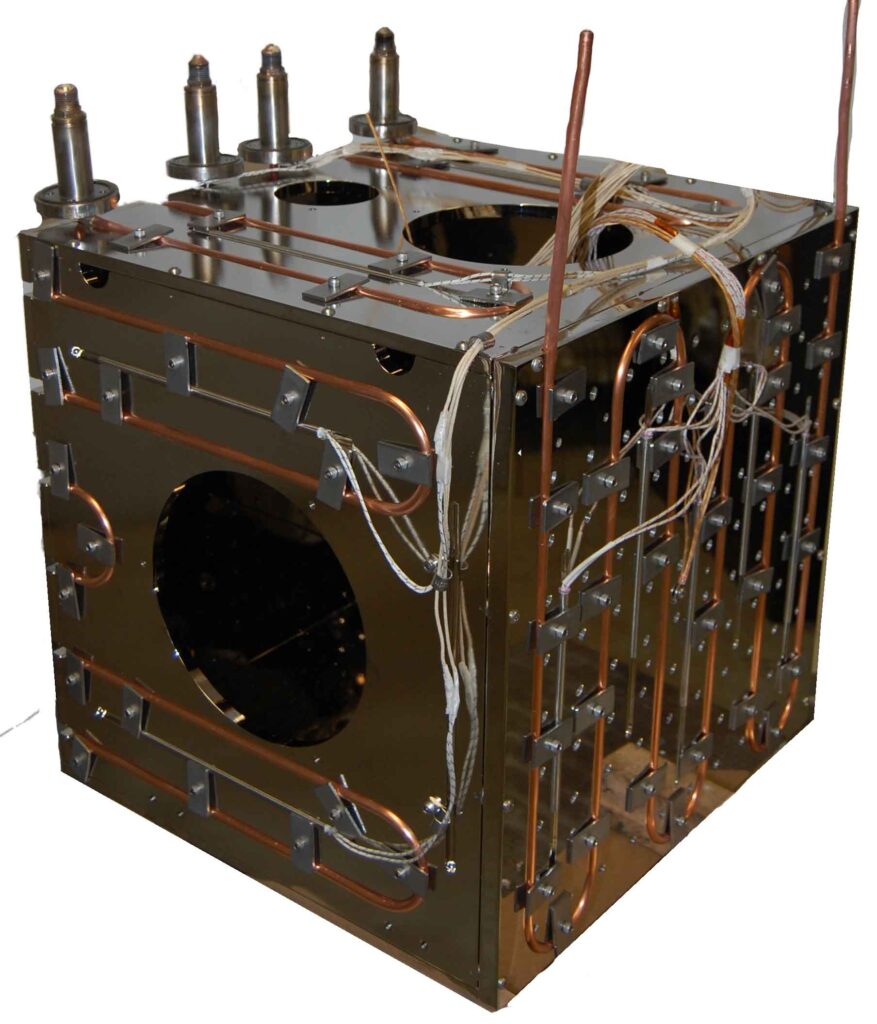

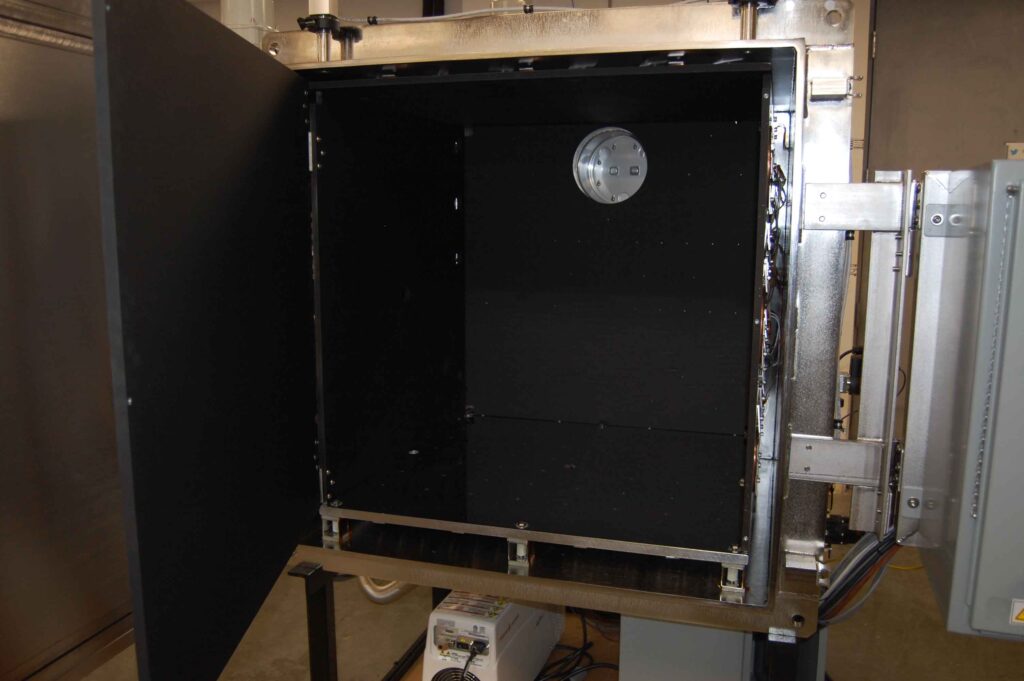

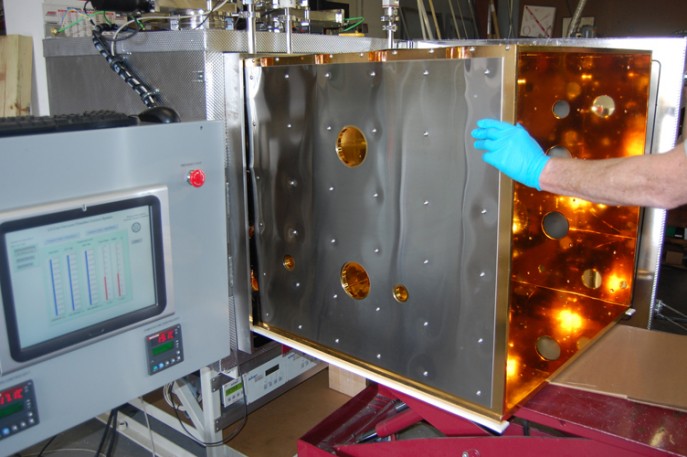

A shroud assembly of Thermal Plates with cable heating elements and cooling loops bracket mounted within the chamber. Feed-through for electrical power, thermocouple and cooling lines extend through the rear wall of the chamber. If desired, Abbess engineers are able to utilize each thermal plate of the shroud indecently to create a knifes edge thermal zone that is capable of simulating cold temperatures on side of your AUT and hot temperatures on the other.

The thermal shroud allows heating/cooling of items in the chamber under vacuum and is controlled by PID temperature Controller integrated into the Process Control Enclosure.

The Process Control Enclosure contains components necessary for controlling the system as well as logic and interfaces for the Thermal Vacuum Cycle Controller. Status Indicators within the Process Control Enclosure provide visual indication of the systems status. The PC Touchscreen Computer contains Abbess customized DAQFactory program interface: test environment automation and data logging integrates control and monitoring of the thermal vacuum system other components.

Different Types of Finishes and Coatings for your Thermal Shroud:

To get an accurate quote for the system you need fill out our RFQ or call today!

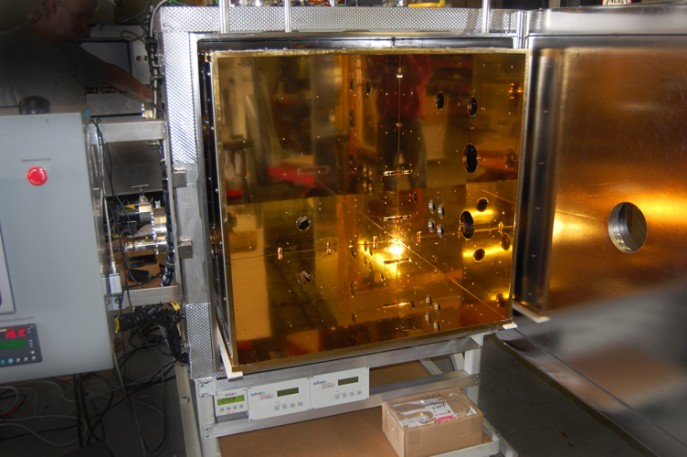

A High vacuum chamber with a thermal shroud being assembled in our facility:

The process of baking out flight hardware is an essential part of a product assurance for any critical project. Our bakeout process is performed to accelerate the outgassing of volatile compounds from your test article, which otherwise might affect your end goal.

Abbess thermal shrouds are an integral part in achieving this process. Non-contact heating of flight hardware within a vacuum environment can be challenging as all heat transfer must be done radiatively rather than through conduction or convection, the biggest effect on the efficiency of the thermal shrouds are its coating or surface treatment.

To get an accurate quote for the system you need fill out our RFQ or call today!