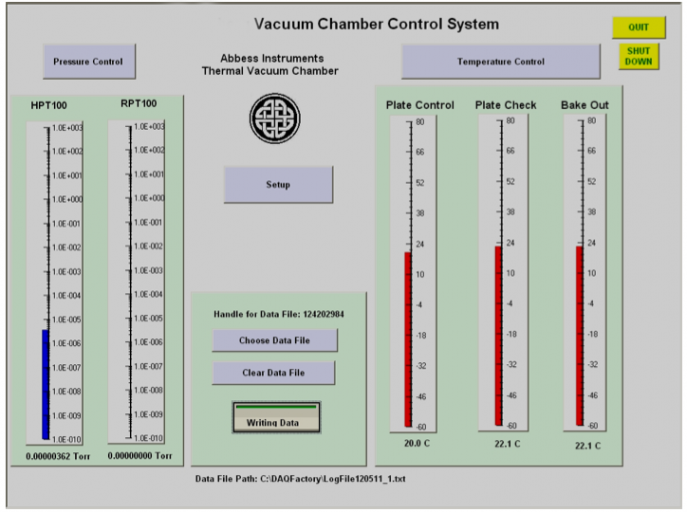

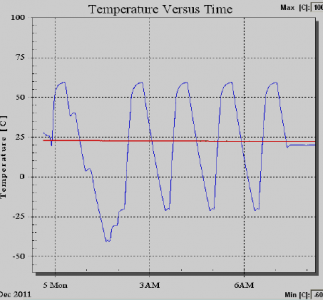

This vacuum chamber system allows articles under test placed inside to be exposed to high vacuum as well as various temperatures via the heated and cooled Thermal Plate Assembly. A computer with PC touch screen, custom programmed GUI is used to automate ramp and hold temperature control functions and log data to a data file that is Excel-compatible.

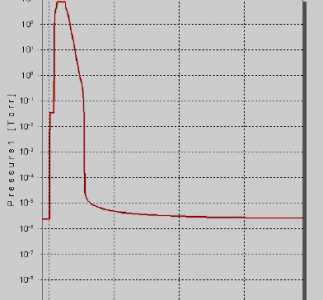

Automated Space Simulation system for 10-6 Torr operation with thermal cycling: The As-Built performance curves shown (Figs: 1 & 2), were obtained at Abbess facilities (188’ elevation).

The automated space simulation system is comprised of:

- Electropolished SS chamber (36”x36”x36”) & door

- Chamber Preconditioning and Contamination Control features:

- Bakeout to 150C

- Inert gas purge (Fig. 1 above curve was attained WITHOUT activating such purge.) With purge pressures as low a 10-8 Torr can be achieved.

- RGA port (RGA ordered separately)

- 24” Au-coated thermal plate

- Custom process ports, feedthroughs, and expansion ports

- -80C Cascade refrigeration subsystem (read more about our cascade refrigeration systems)

- Vacuum pumping subsystem (single Turbo)

- Computer with PC Touch Screen, Custom Programmed GUI