Durable and Versatile Cube Chambers Enable a Variety of Testing Schemes

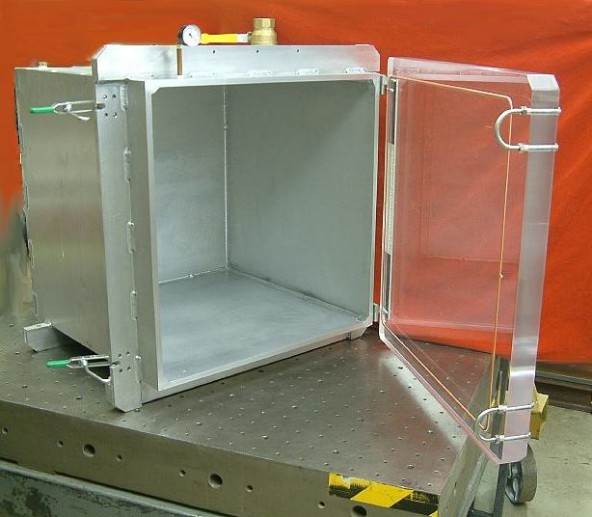

Abbess Chamber Cubes create the vacuum environment for end use testing and process activities in structurally sound and easily accessible rectangular volumes. Standard chambers are provided with hinged, o-ring seal doors in the vacuum chamber material or clear acrylic, which afford user access to the full chamber volume. Custom cube vacuum chambers can be arranged for top loading or custom designed with additional hatch points of access. Vacuum Chambers are provided in materials ranging from electropolished stainless steel, to aluminum, PTFE non-stick coatings, even clear acrylic construction facilitating observation of the articles under vacuum. Scroll down for additional information and examples of our standard and customized Cube Vacuum Chambers. To get an accurate quote for the chamber and system you want, fill out our RFQ or call today!

View Cube Chambers available in Our Store: Abbess Online »Cube Vacuum Chamber – Featured Products:

Side Loading Cube Chamber with Vertical Slide Door

These vertical sliding doors allow for easy access to the interior of your next vacuum chamber system even in confined spaces.

PTFE Non-Stick Coated Vacuum Chambers

These vacuum chambers are designed to be rugged production or testing units for each customers' unique requirements.

Vacuum Mixing & Casting System with PC Based Controller

Complete with vacuum regulation and motor Start/stop contactor

Top Loading Chamber with Lateral Sliding Door

Custom Top Loading Chamber with Lateral Sliding Door Action was produced in answer to a customer's very specific requirements, and on an accelerated timeline.

Thermal Vacuum Gas Mix Test Chamber

The Abbess Thermal Vacuum Custom Gas Mix System allows articles under test placed inside the chamber to be exposed to high vacuum pressure as well as various temperatures via a heated and cooled Main Thermal Plate Assembly.

Achieve dry, and controlled conditions for your items and batches with our process-versatile, multi-access, multi-functional, with a optional automated chamber controller and data logger.

Vacuum Degassing and Oil Fill System

This double-chambered, semi-automated vacuum system allows for degas and Fill processing. (Thumbnail shown with analog VCC)

Large Scale Vacuum Systems, Custom

A custom-designed vacuum system configured to top-load large scale parts into a solution for cleansing/dring/degassing.

These vacuum chambers are in-stock chambers ready for immediate shipment. Next day service available.

These Vacuum Oven Systems are designed and built to be rugged and efficient systems for use in production or testing.

Large Vacuum Storage Systems, Modular

Vacuum Storage System Custom configured to your requirements. complete systems with Pumps, controllers and other options

Top Loading Vacuum Chambers, for Transport in Vacuum or Low Pressure Gas Cover

Doors open on the top of the vacuum chamber. Allows the user to work with a top loading format, place and remove objects in a vertical axis of motion.

Vacuum Oven Systems—Custom configured to your requirements. Complete systems with pumps, controllers and other options

Top and Side Loading Vacuum Chamber with Turntable

Doors open on the top and side of the camber. Windows look onto a rotating turntable within the chamber. LED lights illuminate the interior.

VE-24 and VE-36 Inch Cubes, Non Stick, PTFE

Vacuum Encapsulation, Impregnation, Degassing System—Custom configured to your requirements. 24 inch cubes complete systems with Rotary Mixing, Pouring, liquid Dispencing controls, Heat, Rotary Tables, PTFE non-stick coating, and other options

The tall size of the altitude chamber allows sample carts to be wheeled in with ease. By being able to load the chamber efficiently, it is easier to subject the product sample process to various altitudes. The operable clear acrylic port provides quick and easy access to a test system without needing to unclamp the larger door.

This custom high vacuum chamber with thermal inserts is capable of being used as a large-scale space simulation/thermal vacuum chamber.

24 inch Pressure/Vacuum Chamber

This 24 inch cube is capable of process testing in both vacuum and positive pressure.

This Dual Altitude Chamber System has two separate chambers that function and are controlled independently. This system a facilitates the user to conduct and monitor separate or parallel tests.

The Abbess Thermal Vacuum Chamber System shown facilitates thermal and vacuum profiles consistent with altitudes to 200K feet. Â Customer defined devices are supported with an array of 25 pin D-sub, BNC and SMA feedthrus.

Automated Space Simulation System with -80C Cascade Refrigeration

This system allows articles under test placed inside to be exposed to high vacuum pressure as well as various temperatures via the heated and cooled Thermal Plate Assembly. A Thermal Vacuum Cycle Controller (TVCC) is used to automate and control functions.

High Vacuum System with Thermal Shroud

This 48 inch cube system (thermal vacuum chamber) allows items placed inside to be exposed to vacuum down to 10^-7 Torr. A Vacuum Cycle Controller (VCC) is used to automate control functions.

High Vacuum – Thermal Vacuum System

The Abbess Thermal Vacuum Chamber System shown allows Article(s) Under Test placed inside to be exposed to high vacuum (10e-8 range) as well as heated and cooled via conductive contact with the Gold Plated Copper Thermal Plate.

Multimode Cooling, Thermal Vacuum Chamber System

The Abbess Multimode Thermal Vacuum Chamber System serves as the flexible platform for a range of thermal vacuum testing and experimentation methods. Multimode is cooling using 2 different methods.

Process Passage/In-Line Vacuum Chamber

This in-line vacuum chamber allows an assembly line to go through this vacuum chamber by way of a two-door entry points.

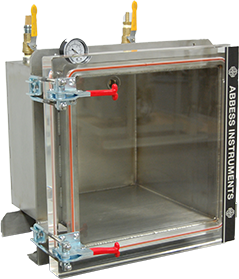

Clear Acrylic Cube Vacuum Chamber

This bench top sized vacuum chamber is designed to be a rugged unit with 1-1/2" thick walls and true o-ring seals for deep vacuums and long life.

Each vacuum chamber with thermal plates can be built to customer requirements (thermal vacuum chamber)

Replicate atmospheric conditions within the vacuum chamber system. This vacuum chamber sytem is ideal for space simulation testing. 6 heated and cooled thermal plates.

Overview of Vacuum Oven Systems

Dry in our manual or automatic, data-logged or not, single or multi-chambered, Vacuum Oven systems.

Low Vacuum – Thermal Vacuum System

The Thermal Vacuum System allows items placed inside of the thermal vacuum chamber to be exposed to vacuum as well as heat or cooled via the Thermal Plate.

24 Inch Cube, Standard Vacuum Chamber

Our standard vacuum chamber is a 24 inch Cube, 24" high x 24" deep x 24" wide, a practical production size for use in vacuum degassing of liquids, plastics resins, and epoxies.

If your product needs to be slid in horizontally into the chamber, see our side loading chambers.

If your product needs to be lowered vertically into the chamber, see our top loading chambers.