Subject your medical, pharmaceutical, food, electronics, and aerospace products and/or packaging to the minimum or range of pressures that they must survive, and/or operate in, as they are trucked/flown or used around the world at various altitudes. Abbess Instruments has a wide portfolio of Altitude Test systems to suit your needs in addressing DOT and FAA ASTM test requirements: Since altitude, from sea level to space, can be associated with a particular pressure, all our vacuum chambers seen on this website can be described and used as Altitude Test Chambers. Please refer to our Space Simulation Test Systems page for tests requiring space altitudes (pressures .10 torr to 10-4 Torr). For the purpose of this page, Abbess defines ‘Altitude Test Systems’ as those systems that simulate altitudes of up to 200,000 ft (760 torr to .10 Torr).

To get an accurate quote for the system you need fill out our RFQ or call today!

Basic System | Standard System | Advanced System | Typical Performance Data | Upgrade Options

View our Altitude Testing Products

Basic Control System

Features of a Basic altitude control system are:

- ON/OFF control of chamber altitude in thousands of feet up to 200k feet

- Setpoint control

- 40 step altitude profiles

- Digital readout of pressure and altitude

Includes: - Solenoid vent and vacuum valves

- Digital Pirani pressure gauge

- Watlow PID altitude controllers

The basic control package will permit a single ‘automatic’ altitude/vacuum set point, whereas the standard and advanced control packages allow for full altitude/flight ‘climb & Dive’ profile simulation functionality.

Where there is limited counter space or large batch sizes, the entire system can be integrated on a cart using identical or mixed-sized, chambers. Since cart mounted systems are shipped turn-key, set-up is minimal. Cart-mounting provides full system mobility and thus flexibility of positioning on your production floor.

To get an accurate quote for the system you need fill out our RFQ or call today!

Standard Control System

Benefits:

- Cost effective solution to precise altitude simulation

- Simple and easy to operate user interface

- Precise control of altitude up to 200,000ft

- Editable PID configuration with auto-tuning capabilities

- Ramp rate control (in Kft/min) for climb and dive simulation

- Rs-485 compatible

- Up to 40 step profiles

Standard Features:

- Proportional Valves for climb and drive ramp rate control and more precise level altitude control

- Watlow F4T PID Altitude Controller enable multistep profile sequences, displays units in feet

- Instrutech Superbee convection-enhanced Pirani pressure gauge with linear 0-10V output

Abbess engineers will work with you to customize a Test System to meet your needs. Customization can be achieved via the introduction of a wide range of features and feed-through components for your Article Under Test, control configurations, as well as data-logging and process profile automation.

To get an accurate quote for the system you need fill out our RFQ or call today!

Advanced Control System

Benefits:

- Simple and easy to operate custom graphical user interface capable of graphing and logging data as well as intuitive system control

- Precise control of altitude up to 200,000ft

- Editable PID configuration with auto-tunning capabilities

- Ramp rate control (in Kft/min) for climb and dive simulation

- Rs-485 compatible

- Unlimited step altitude profiles

- Digital readout of pressure and altitude

Standard Features:

- Valbia Proportional Valves for climb and drive ramp rate control and more precise level altitude control

- Watlow F4T PID Controller that enables multistep profile sequences

- Instrutech Superbee convection-enhanced Pirani pressure gauge with linear 0-10V output

- Industrial Touch Screen PC mounted in a NEMA Enclosure

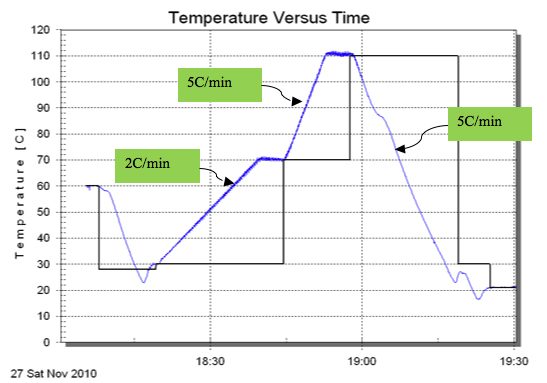

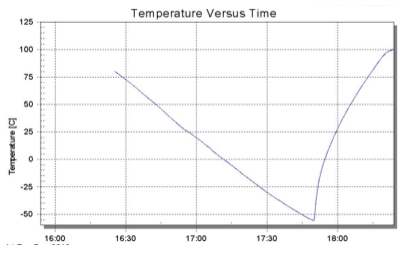

Monitoring and control of systems are attuned to the customer’s specified process needs which, for “Climb & Dive” and/or thermal profiling, requires a PC Touch Screen package. An example of a thermal profiling is shown below in fig. 6. Manual and automatic valve operation and pump control are configured to both optimize operation time and assure the proper cycling of vacuum equipment.

To get an accurate quote for the system you need fill out our RFQ or call today!

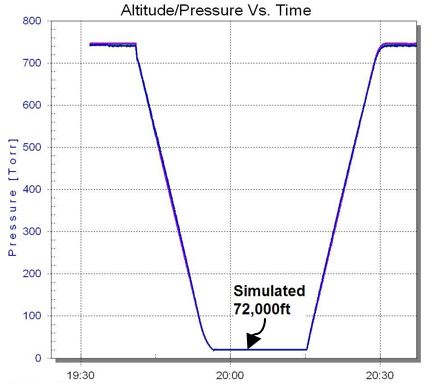

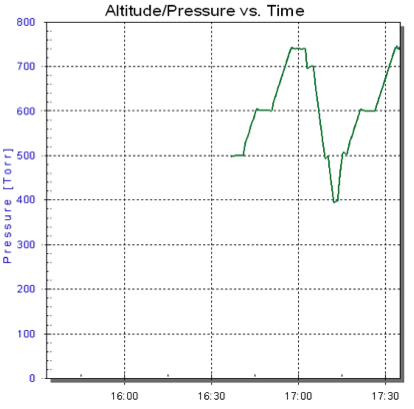

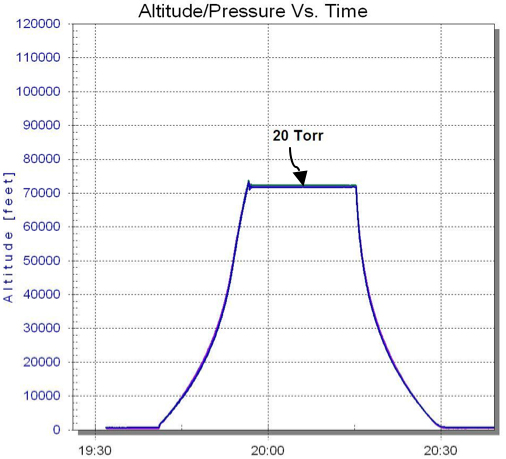

Typical Performance Data

The following sample data were taken from 48” cube chambers. Testing is performed in CDE chambers at our Facility in Holliston, MA (188’ elevation).

Typical Performance Summary see Table 1

- “Climb & Dive” Pressure Profile Examples: in Torr

- “Climb & Dive” Pressure Profile Example: in Feet

- Thermal Plate Performance Example

| Space Simulation System Performance 48” Cube | ||

| Operational Vacuum | 10-6 Torr | For an empty, clean chamber at sea level … over all Temp ranges |

| Vacuum Ramps | Pump Down Ramp: 10-5 Torr in 3 hrs. | For an empty, clean chamber at sea level |

| Vacuum Relief Ramp: < 3 mins | ||

| Deep Space Vacuum Stability | Within 1×10-9 Torr over several minutes

Within 0.2×10-7 over 12h 49m | Measured at 10-7 Torr |

| Thermal Range | -150 °C to +150 °C | Of thermal plates |

| Thermal Ramps | Fast Ramp: | Over the range -60 °C to +100 °C heating and cooling |

| 3 °C/min | Using 22psi LN2 tanks | |

| 6 °C/min | Using 235 psi LN2 tanks | |

| Slow Ramp: 1 °C/min | ||

Note that a simulated “Climb” in altitude presents as a drop/dive in Torr: i.e. pressure drops as altitude increases.

- Pressure Dive from 740 Torr to 700 Torr at 50 Torr/min and soak for 1min;

- Pressure Dive further to 500 Torr at 50 Torr/min and soak for 1 min;

- Pressure Dive further to 400 Torr at 50 Torr/min and soak for 1 min;

- Pressure Climb to 500 Torr at 50 Torr/min and soak for 1 min;

- Pressure Climb further to 600 Torr at 20 Torr/min and soak for 5 min;

- Pressure Climb further to 740 Torr at 20 Torr/min and soak for 1 min.

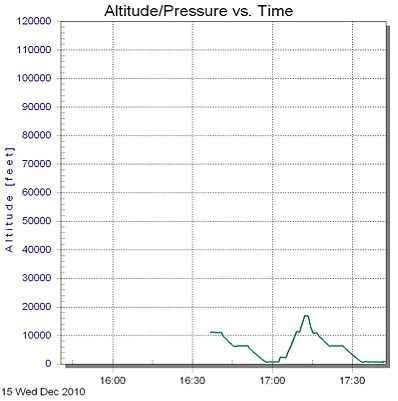

“Climb & Dive” Pressure Profile Example: in Feet

Note that a simulated “Climb” in altitude presents as a drop/dive in Torr: i.e. pressure drops as altitude increases.

The system operates in Torr; any values the operator inputs as feet are converted by the system for monitoring and control purposes. All ramps are linear in Torr, but non-linear in ft or meters (the average ft or m ramp rates achieved are those set by the operator).

Thermal Plate Performance Example

To get an accurate quote for the system you need fill out our RFQ or call today!

Upgrade Options

Upgrade options include:

- Mobile cart; or heavy duty in-built casters for the largest systems.

- Heating and/or cooling thermal plates/shelving and control:

for heating up to +200C) (as illustrated in the Vacuum Oven System).

and/or for cooling to -150C (as illustrated in the Space Simulation and Thermal Vacuum System). - Humidity Monitoring/Control

- Shelving .

- Inert gas purge.

- Circulation fans.

- Mechanical feedthroughs such as shafts with or without rotation.

- Electrical feedthroughs for power and signals.

- Optical ports for optimal transmission of test equipment wavelengths

- Hold down fixture (often required to keep empty packaging submersed under liquid.

- Drains, and/or spill trays.

- Special coatings such as PTFE non-stick coating, FDA-approved

- Switchable, internal lighting

- Viewports

- Lighting

Abbess can help you. Successfully test your high-value inventory in our manual or automatic, data-logged or not, single or multi-chambered, Altitude Test systems. To get an accurate quote for the system you need fill out our RFQ or call today!