The Abbess High Vacuum Thermal System allows test articles to be placed inside and be exposed to high vacuum pressure as well as extreme temperatures via the integration of a cascade chiller and electrical heating elements. This thermal vacuum chamber system is controlled by a PC with a user-specific Graphical User Interface (GUI). In conjunction with a Vacuum Cycle Controller (VCC), the system can regulate and control the vacuum level and automate many of the process control functions.

To get an accurate quote for the system you need fill out our RFQ or call today!

Thermal Cycling of Space Hardware System:

- Electropolished SS chamber (24”x24”x24”) & door

- Chamber Preconditioning Bake out and Contamination Control features:

- Bake out to +150C with the use of internal or external heaters

- Inert Gas Purge

- RGA port (RGA ordered separately)

- 20” Ni-coated thermal plate and shroud

- Custom process ports, feedthroughs, and expansion ports

- -96C Cascade chiller refrigeration sub-system (read more about our cascade refrigeration systems)

- Dry Vacuum pumping system

- Computer with PC Touch Screen and Custom Programmed GUI

TVAC Systems with shrouds allow for reliable and uniform cooling/heating under vacuum.

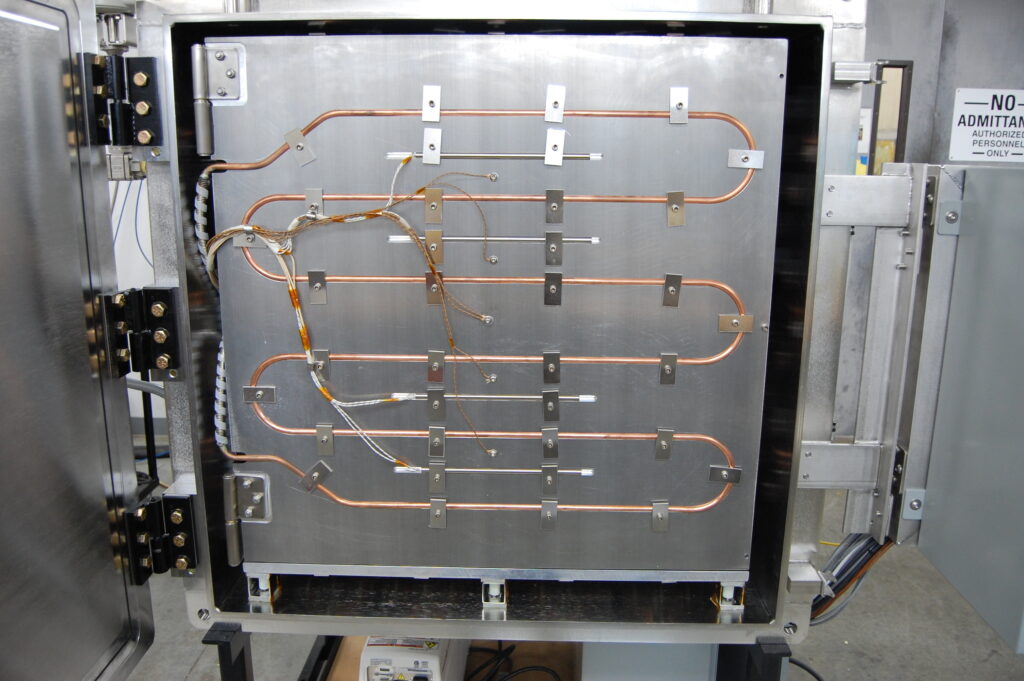

The shroud assembly and Thermal Plates with cartriage heating elements and cooling loop brackets mounted to the exterior of the thermal plates and shroud. Feed-through for electrical power, thermocouple and cooling lines extend through the rear wall of the chamber. The thermal shroud allows heating/cooling of items in the chamber under vacuum and is controlled by PID temperature Controller integrated into the Process Control Enclosure.

The Process Control Enclosure contains components necessary for controlling the system as well as logic and interfaces for the Thermal Vacuum Cycle Controller. Status Indicators within the Process Control Enclosure provide visual indication of the systems status. The PC Touchscreen Computer contains Abbess customized DAQFactory program interface: test environment automation and data logging integrates control and monitoring of the thermal vacuum system other components.

With the integration of the Snow River® C80-6 cascade chiller we are able to eliminate the high running cost of liquid nitrogen systems and offer precise control across a wide range of temperatures from -96C to +200C. This is achieved by a 20 gallon tank filled that is filled with syltherm oil. Then there’s the cascade refrigeration, which consists of two loops: a low stage with 508b refrigerant, and a high stage with 404a refrigerant. The high stage (404a) runs continuously to cool the heat exchanger which is used as a condenser by the low stage. This allows the low stage to cool the thermal transfer fluid passing through its evaporator to -96C.

Independent Thermal Zones

In other renditions of this we are able to independently control each thermal zone (plate and shroud) in order to recreated thermal variations on planetary surfaces.

Allows control over the rate of temperature change for each shroud plate to ensure a uniform temperature gradient across the test article and can be controlled either to provide a slow uniform heating or to deliberately maintain regions of varying temperature.

To get an accurate quote for the system you need fill out our RFQ or call today!

Thermal Vacuum Featured Products:

no posts foundLooking for higher vacuum than 10^-6 torr? See our Space Simulation Systems.

If you are looking to heatseal your products, please see our Sealers.

Our thermal test chambers allow you to simulate what you need. To get an accurate quote for the system you need fill out our RFQ or call today!