Features include

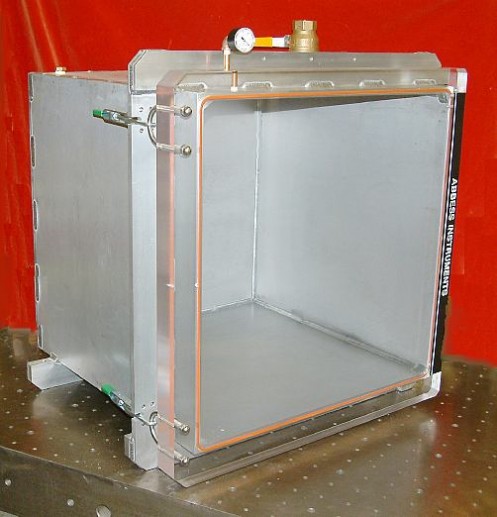

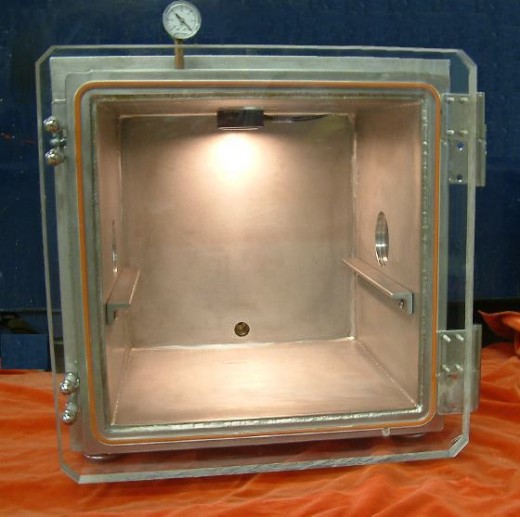

- Vacuum Chamber (15″ ID x 10″ DP shown)

- Vacuum Pumping System w/Inlet and Exhaust Filters

- Optional Automated Vacuum Cycle Control

- 1000 lb cap. Heavy gauge, Welded Steel Cart

- Size 33H x 32L x 20W other sizes special order

- Your system comes to you complete, ready to plug in and GO!

Abbess provides complete chamber systems for degassing, mixing, dispensing, sealing, and other vacuum work that include a leak tested, o-ring sealed vacuum chamber and a fully integrated pumping system with pump, vacuum grade hose, filters, valves, and gauge. Chambers can be configured for manual valve operation or provided with Automated Vacuum Cycle Control. Abbess can also equip these systems with features such as heated thermal plates and variable speed in-vacuum motorized mixing, liquid feed throughs, custom valve arrangements -really whatever the process requires.

Other chamber configurations and components are described at our Abbess Vacuum Products page.

Your choice of Vacuum Chamber and pump complete and ready to GO!

Select any Abbess Vacuum chamber and pump we will mount and test it on a cart with a vacuum pump, filter hose, valves, and fittings.

Most of our other vacuum chambers can be installed onto carts.

Items to Customize your Vacuum System

Vacuum pump, filter, hose, gauge, valves – Use these items to complete your vacuum chamber system.

- Vacuum pumps – see our Standard vacuum pumps

- Vacuum Fittings – as required

- Liquid Epoxy/Resin Vacuum Feed-Through

- Use it to fill molds under vacuum,

- No more bubbles in your product

Includes special chamber fitting, pinch valve and hose.

Hose inner diameters from 1/16″ up to 1/2″ are in stock.

Liquid Epoxy/Resin Vacuum Feed-Through

- Rotary Vacuum Feed-Through

Use it to rotate parts or with your mixer to mix resins under vacuum, prevents air entrapment before it happens.

Shaft diameter is 3/8″ with 1/2″ coupler.

- Liquid Epoxy/Resin -IN- Vacuum Mixing

- NO Air No bubbles!

If you mix under vacuum you cannot have air bubbles in the first place.