Advanced Thermal Vacuum System for Custom Gas Environment Simulation

Thermal Gas Mix Thermal Vacuum (TVAC) systems are essential for simulating harsh and highly specific environmental conditions, such as those encountered in space or on other planetary bodies. By combining high vacuum capabilities with precise thermal control and programmable gas mixture inputs, these systems allow researchers and engineers to create controlled environments that closely mimic real-world operational settings. This is particularly useful for testing aerospace components, electronics, sensors, and materials that must withstand extreme temperatures, pressure fluctuations, and reactive or rare gas atmospheres. The ability to mix multiple gases with high accuracy enables simulation of environments like Martian, lunar, or deep-space atmospheres, providing critical insight into performance and durability under mission-specific conditions. Beyond environmental simulation, TVAC systems support extensive product validation and reliability testing. They help detect outgassing, monitor material degradation, and evaluate the long-term performance of assemblies under cyclic stress. Advanced systems include integrated software for automated testing, real-time data logging, and system control, ensuring consistency and traceability. These capabilities make TVAC systems indispensable in industries such as aerospace, defense, semiconductors, and scientific research, where failure is not an option and components must be proven under the most rigorous standards.

Key Features

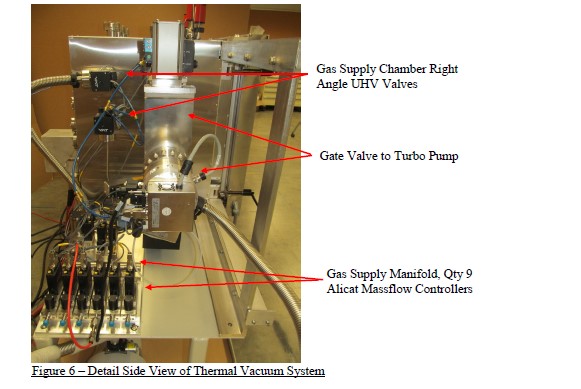

- Custom Gas Mixture Capability: Equipped with mass flow controllers, the system can mix up to six different gases, allowing for the simulation of diverse atmospheric compositions.

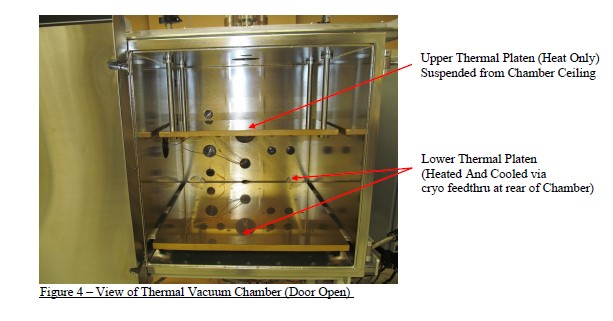

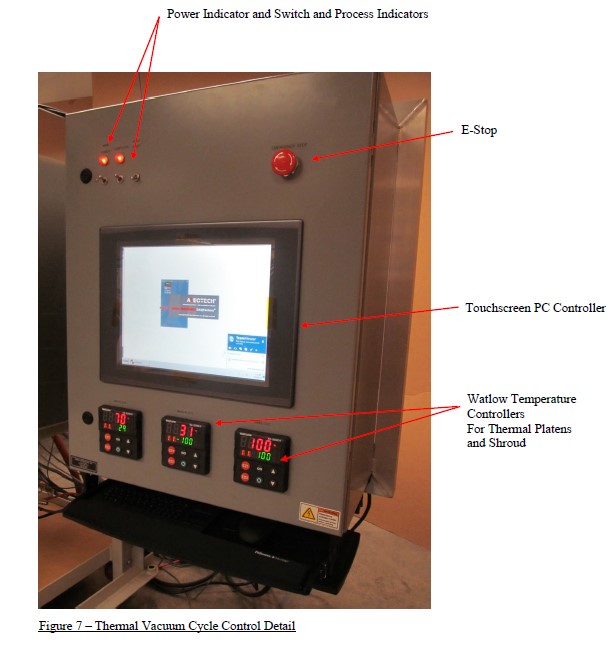

- Advanced Thermal Control: The chamber features a heated and cooled main thermal plate assembly, with an optional secondary platen for additional radiative heat sources, enabling precise temperature regulation during testing.

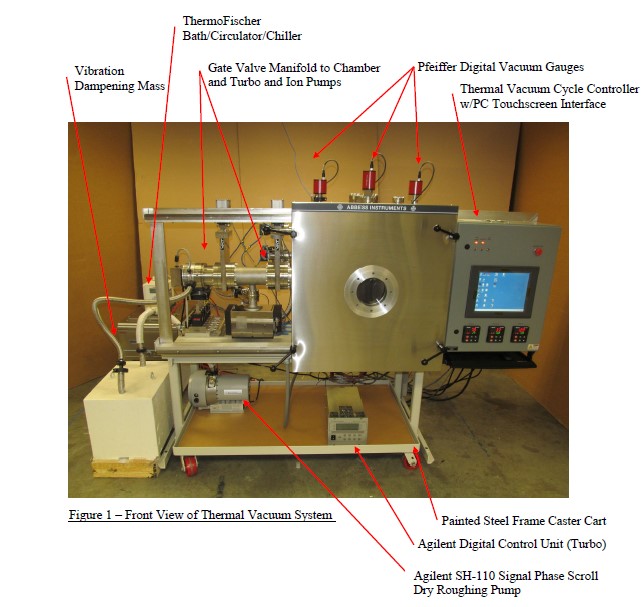

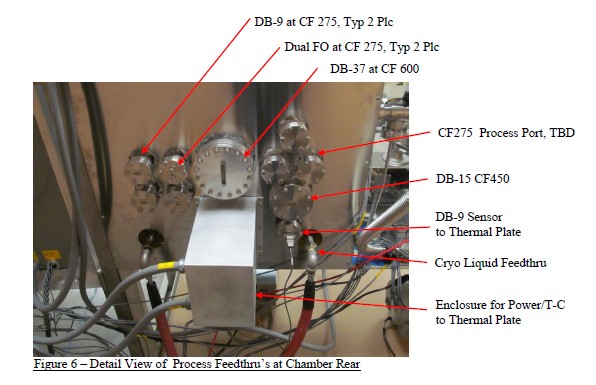

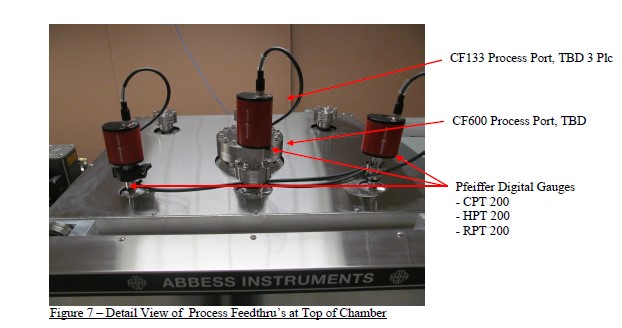

- Integrated Control System: A Touch Screen/PC GUI Thermal Vacuum Cycle Controller (TVCC) manages all system functions, including turbo pumping speed, gate valve manifold configuration, thermal platen temperatures, and gas mixture flow. The TVCC also logs performance data and allows for user-specific graphical interfaces.

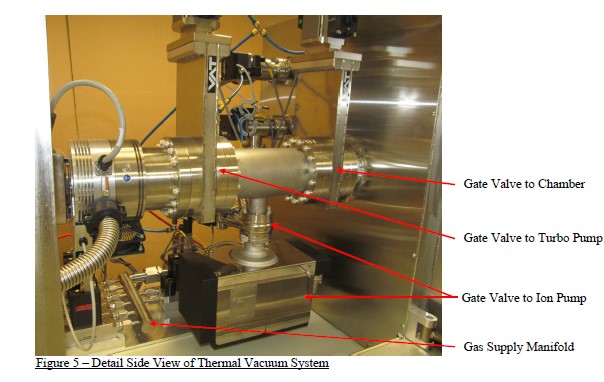

- Flexible Pumping Configuration: The system includes a gate valve manifold that supports various pumping configurations, including turbo molecular pumps backed by dry scroll pumps and ion pumps, catering to experiments requiring ultra-high vacuum conditions.

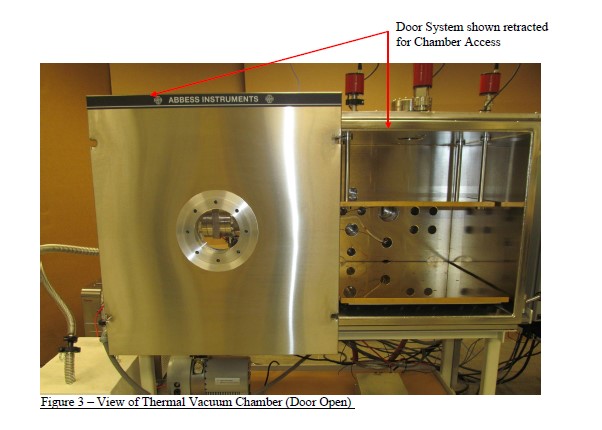

- User-Centric Design: The chamber’s design incorporates a sliding door gate valve manifold, a plenum manifold, and UHV right-angle valves, facilitating the combination of multiple gas sources and the administration of gases across a range of process pressures.

Applications:

- Planetary simulation of different gaseous environments

- Outgassing behavior analysis

- Environmental stress screening

- Scientific research involving atmospheric simulation