Abbess Instruments’ Thermal Vacuum and Solar Simulation Chamber Systems are designed and produced for use in laboratory production and testing applications requiring an exposure to or process within a controlled vacuum environment at specific temperature involving solar simulation. The chambers are often custom designed for specific end-user requirements in test applications recreating extreme atmosphere and temperature situations and illuminations. Our customers use our full range of vacuum systems for testing or degassing packaged products, liquids and solids, for EMI and altitude testing of electronics, computers and complete systems, shock impact targets, plasma, space simulation or degassing large parts or components for research, and development.

Abbess designs rugged equipment and practical systems for continuous and demanding analytical, manufacturing and production use, with safety and a long life in mind. The vacuum chambers are constructed of heavy aluminum, steel or stainless steel and feature customer replaceable O-ring seals, designed and fabricated to withstand repeated opening and reseal actions. Chambers are He leak tested to a rate of 10-7 cc per second, or better as required by end user needs, and are designed to maintain this level for extended robust use dependent on seal condition and customer practice.

System Description

The Abbess Thermal Vacuum Solar Simulation System allows articles under test placed inside to be exposed to high vacuum pressure as well as various temperatures via the heated and cooled Thermal Platen and Shroud Assembly. A Thermal Vacuum Cycle Controller (TVCC) is used to automate control functions. The TVCC enables system control via panel-mounted buttons and indicators and by a Touchscreen PC with a user-specific Graphical User Interface (GUI).

The Thermal Vacuum Solar Simulation System consists of the following major components

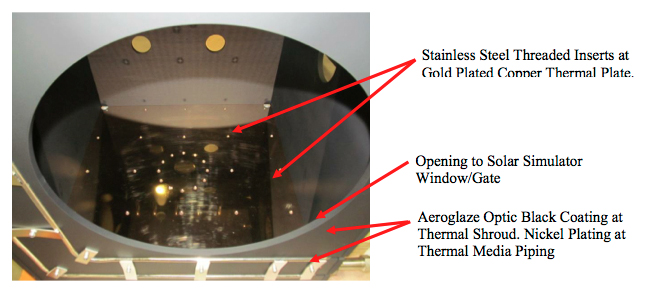

- Vacuum Chamber – A front loading Stainless Steel Chamber, with attendant equipment and process feedthru’s mounted upon a heavy-duty cart/stand. Chamber vacuum environment surfaces are electropolished and heated by an insulated Chamber Bakeout System which serves to excite and desorb particles from the chamber wall and together the purge gas control kit serve to condition the chamber for Hi Vacuum performance (to 10e-5 Torr range).

- Thermal Platen/Shroud – Copper Thermal Plate Assembly and Shroud mounted within the chamber with engaged heating/cooling loop. Feedthru for sensors and cooling lines extend through the rear of the chamber and render the Gold plated Thermal Plate and Shroud thermally active. The platen/shroud assembly facilitates controlled heating/cooling profiles of article(s) under test in the chamber under vacuum. These are controlled by on board Temperature Control on the Thermal Bath Circulator Systems and Limit Controller mounted in Process Control Enclosure and integrated into the Control interface provided by the PC Touchscreen.

- Process Control Enclosure – Contains components necessary for controlling the system as well as logic and interfaces for the Thermal Vacuum Cycle Controller.

- Temperature Controllers.

- Status Indicators

- Vacuum Cycle Controller

- PC Touchscreen Computer

- Turbo Pump System

- Roughing Pump

- Turbo Pump

- Pressure Gauges

- Pressure Transducers

- Control Valves

- Pneumatically Actuated Gate Valves

- Electromagnetic Right Angle Valve

- Manual Vacuum Break

- Process Ports

- Customer defined ports to provide test/process feedthru into the thermal vacuum environment.

- Solar Simulation Subsystem

To get an accurate quote or to discuss your vacuum needs, fill out our RFQ or call today!

Thermal Vacuum Cycle Control Theory of Operation

The Abbess Thermal Vacuum Solar Simulation System approximates specific thermal, vacuum pressure and illumination conditions in order to observe articles under test which might experience these same conditions in actual use. Vacuum and temperature conditions are established within the chamber that recreate target thermal and pressure extremes. Illumination is provided by a separate 1.6 KW 1 Sun Illumination System and Window/Gate Valve assembly. On board Controls activate the thermal system components, with a thermal plate and shroud which reside within the vacuum chamber. The Turbo Molecular pumping system which evacuates the chamber environment is powered by the Digital Control Unit (DCU) with pressure data provide by two separate Digital Vacuum Gauges.