WANT TO SEE THE SYSTEM IN ACTION?

WATCH THE VIDEO HERE!

Read more about the system and its function here!

The NASA Scientific Visualization Studio’s project titled “Sample Analysis at Mars (SAM)” provides an in-depth look at a suite of instruments designed to analyze Martian soil and atmosphere. Developed through an international collaboration involving NASA’s Goddard Space Flight Center, the Jet Propulsion Laboratory, the University of Paris, and Honeybee Robotics, SAM aims to detect key elements such as water and carbon to determine if Mars ever supported life.

The project features a series of videos highlighting the mission’s objectives and the contributions of various team members. One video focuses on Jess Lewis, who designed SAM’s Solid Sample Inlet Tube (SSIT), a device that directs Martian soil into the SAM suite for analysis. Another video profiles Dan Carrigan, the engineer responsible for building SAM’s Quadrupole Mass Spectrometer (QMS), which breaks down Martian soil and atmosphere into their components for identification. Additionally, a video showcases Synthia Tonn, a junior engineer who manages SAM’s ground support equipment and the intricate gas lines connecting its instruments.

These visualizations not only illustrate the technical aspects of SAM but also emphasize the collaborative efforts behind this ambitious mission to explore the potential for life on Mars.

For more information and access to the videos, you can visit the NASA Scientific Visualization Studio’s page on SAM HERE.

Vacuum Chamber

The Vacuum Chamber body consists of the following:

-

- Inside Dimensions: 36″ wide x 36″ deep x 36″ high

-

- Material: Electropolished Stainless Steel 304

-

- Door Material: Electropolished Stainless Steel 304, mounted on front side, hinged on right, two door clamps on left side

-

- Door Seals: Viton O-Ring

The chamber is designed and tested to reach an ultimate pressure of 10E-7 Torr at room temperature after Bakeout. Measurement of the pressure inside the chamber is achieved through a Terranova® Model 990 Controller with Inficon BPG-400 Wide-Range Sensor, 13 Decade Auto-Ranging Vacuum Measurement with a Single Port. The Terranova 990 controller provides two pressure set points with relay outputs. Both set points have independent High and Low settings to allow the user to set the hysteresis of the set point operation. As the system is pumped down, the set point relay will be energized (set point turns on) as the pressure drops below Set Point Low. The relay will remain energized until the pressure rises above Set Point High.

Thermal Controls

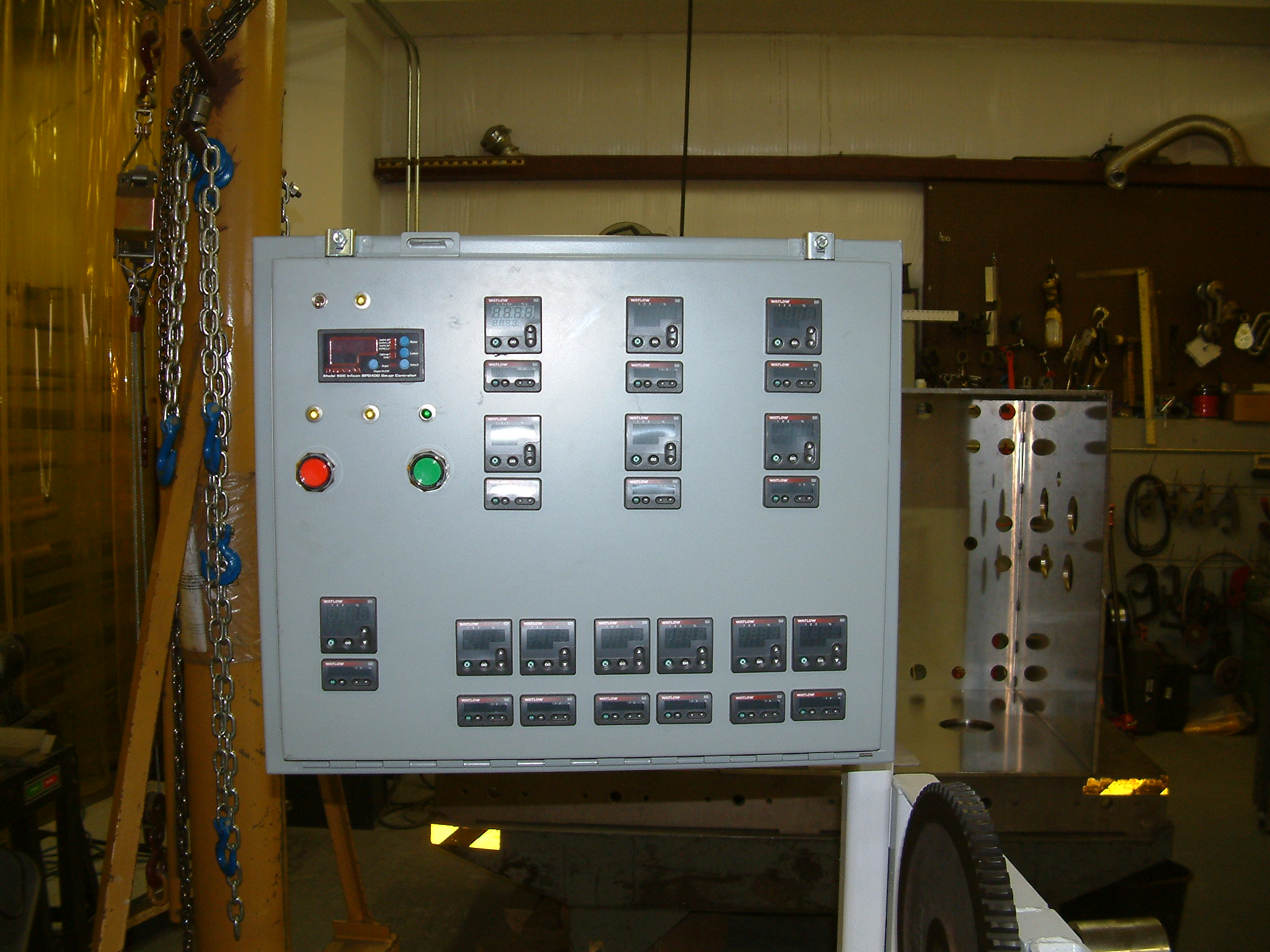

To facilitate bakeout of the chamber to +200C, heating elements are attached to the external walls of chamber. An insulation blanket is used over these elements to improve thermal efficiency and safety. These external heating elements are controlled with Watlow SD Series PID Temperature controllers mounted in the Vacuum System Control Panel.(Shown above).

Mounted internal to the chamber are the SAM Thermal Plates and Shroud Panels used to make up the 6 SAM Thermal Plate Zones. Each thermal plate corresponds to a temperature control group used to emulate the various temperature profiles experienced by the SAM’s surfaces when mounted in the WEB of the MSL. A cold gas manifold and solenoid valves are used to supply the SAM thermal plates with Gaseous Nitrogen for cooling from a Liquid Nitrogen Dewars. Electrical heater loops are embedded in/on each SAM Thermal Plate and Shroud Panel.