Abbess offers a full range of vacuum chambers by Type:

Round/Tube Vacuum Chambers

Acrylic Vacuum Chambers

This bench top sized vacuum chamber is designed to be a rugged unit with 1/2″

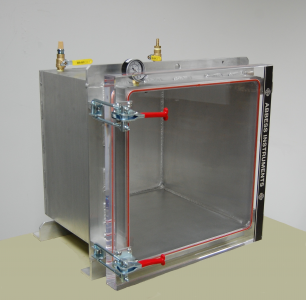

Square or Cube Vacuum Chambers

[bws_productlist title=’Side Loading Vacuum Chambers’ search=’product_tag’ theme=’blue’ terms=’side-loading’ /]

[bws_productlist title=’Top Loading Vacuum Chambers’ search=’product_tag’ theme=’violet’ terms=’top-loading’ /]

[bws_productlist title=’Multi Chamber Systems’ search=’product_tag’ theme=’yellow’ terms=’multi-chamber’ /]