Downloads

- System Drawing (Coming Soon)

- User Manual (Coming Soon)

- Product Brochure (Coming Soon)

- Product Vacuum Graphs (Coming Soon)

- Products Thermal Graphs (Coming Soon)

Description

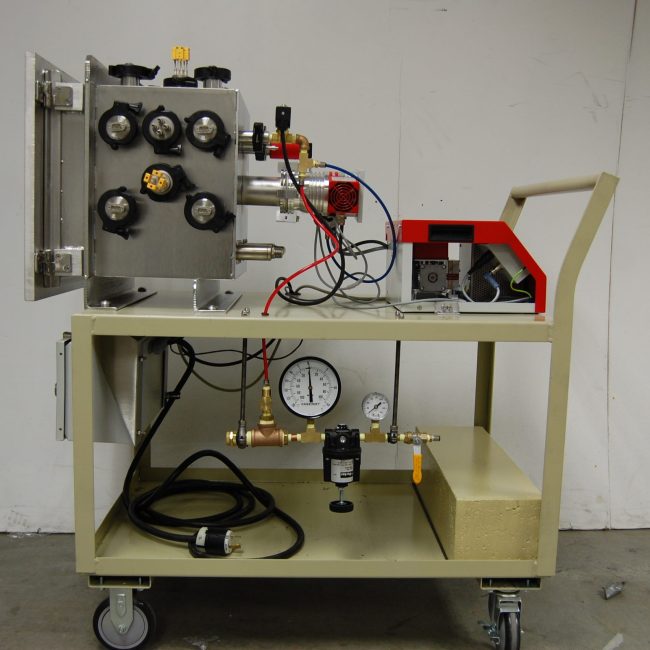

Entry Level High Vacuum Thermal System (TVAC) Configuration:

See the performance graph PDF download above for all option’s performance data.

- 14″ Welded Stainless Steel Cube Chamber

- 12″ x 12″ Heated and Cooled Thermal Platen (-175°C to +200°C)

- Stainless Steel Front Chamber Door

- Leybold or Pfeiffer High Vacuum Pump Package

- Two ISO LF200 ports which allows for a variety of feedthroughs to be added from either side of the chamber

- Abbess’ Basic Purge Kit

Abbess Entry Level High Vacuum thermal system allows for process and test instruments to create precise environments empowering the operator with complete control over internal chamber pressure and temperature. They are built with innovation in mind. They allow for prototype device exploration in vacuum during the product research and development phase and for precise process control in small batch processing. These thermal vacuum test chamber instruments are designed to allow users to quickly tailor experiments to gather product analysis and diagnostics data as the product is subjected to the extreme stress factors of vacuum and temperature.

Abbess Entry High Vacuum Thermal System is just our entry level system but is completely customizable if desired. Feel free to contact us with your requirements and we can tailor the system to your exact needs.

Abbess Entry Level TVAC System Configuration Options:

- Roughing Pump (dry scroll or dry multi-stage roots, various speeds)

- High Vacuum (various speeds)

- Full Vacuum Pressure Control

- Heated and Cooled Platen

- Chamber Wall Heating

- Integrated Chamber Lighting

- Closed-Loop Refrigerated or Ln2 Cryogenic Cooling System

- Automated Software Control

- Remote Control Operation

- Purge Ports, Chamber Shelving, etc.

A wide range of vacuum chambers is available with internal cubic sizes of 14, 18, 24, or 36 inches. These chambers can be constructed from either aluminum or stainless steel, depending on user preference.

The TVAC system features an intuitive front panel with a colored LED pushbutton interface, allowing easy control of all chamber functions. PID controllers and gauges are installed based on the user-selected options. A PLC oversees system operations, including pump and valve sequencing for efficient pump-down cycles, along with safety interlocks to protect equipment from damage. The system’s electronics are housed in a conveniently accessible, built-in NEMA-style enclosure.

Two large LF200 side port is available for user-customized accessories, such as electronic feedthroughs for device monitoring or shock testing, infrared lamp arrays for radiant heating or temperature differential tests, and ultraviolet lamp arrays for ionizing radiation tests. For customized rise rates, additional vacuum pumps can be mounted outside the cabinet.

Typical Applications for this System:

- Collegiate Research and Development

- Altitude Test Chamber

- Space Simulation Test Chamber

- Thermal Shock Chamber

- Aerospace & Aeronautical Engineering Test Chamber

- High Altitude Flight Component Testing

- Vacuum Oven

- Vacuum Freeze Drying

- Plastic & Epoxy Curing & Outgassing