Overview

Description

- 24″ x 24″ x 72″H Aluminum Vacuum Chamber

- Clear Acrylic Chamber Door

- Variety of Vacuum Pumps available

- Various ports which allows for a variety of feedthroughs to be added from the back side of the chamber

- Abbess’ Standard Purge Kit

Read more about the control logic of our Advanced Altitude Simulation Systems below!

Description

Advanced Altitude Simulation System

Abbess Advanced Altitude Simulation Systems are designed for precise pressure control experiments, including rapid compression and decompression testing. Operating in the range from Sea Level to 250,000 feet, providing accuracy within the limits of the built-in vacuum pressure gauge sensor. Our fully integrated, turnkey simulation systems feature a welded vacuum chamber, hinged acrylic door with all required valving to precisely control your altitude simulation.

Each system is paired with a vacuum pump customized to meet any of your product cleanliness requirements and vacuum specifications. Chamber venting and pumping is managed by our intuitive valving setup enabling pressurization rates of up to 50 Torr per second—faster than the acceleration felt during freefall.

Operators can select from multiple pressure units, including Altitude, Torr, Atmospheres, Bar, Pascals, or PSI. Our standard systems are designed to withstand pressures well beyond most ASTM and MIL-STD specifications (10E-3 Torr).

| Materials: |

|

| Interior Dimensions: |

|

| Chamber Options: |

|

| Additional Features/Items: |

|

About Abbess Altitude Simulation Systems

Various industries require the design, testing, and validation of parts, components, and electronics that must function under fluctuating pressures or rapid pressure changes. Aerospace and aeronautical engineers, for example, must create components that can withstand the stresses of takeoff, landing, and high-altitude cruising, whether in commercial aircraft or military and acrobatic planes. Aircraft components need to endure emergency conditions such as rapid decompression inside a pressurized cabin, sudden pressurization during unexpected dives, or extreme pressure variations in storm systems.

Testing components at actual altitudes, especially with rapid pressure changes, is both difficult and expensive. An altitude simulation chamber with controlled interior pressure is often a more efficient solution. Our Altitude Simulation Test Chambers provide precise pressure and altitude control, with accurate ramp rates and setpoint control.

All of our Standard Altitude Simulation systems feature a chamber pressurization rate of 10 Torr per second (*pump dependent), which is faster than the pressure changes an object experiences during terminal-velocity free-fall. This pressurization rate meets most ASTM and MIL-STD rapid pressurization standards. For more demanding applications, such as military aircraft or rocket takeoff simulations, smaller chamber sizes or higher pumping speeds are available to meet MIL-STD-810-G rapid decompression standards.

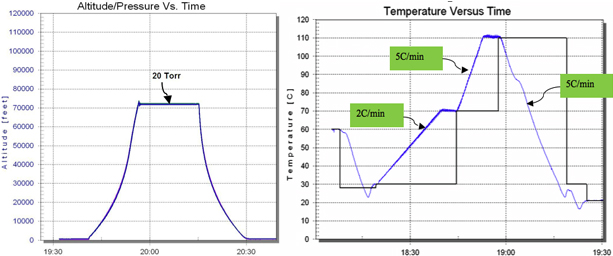

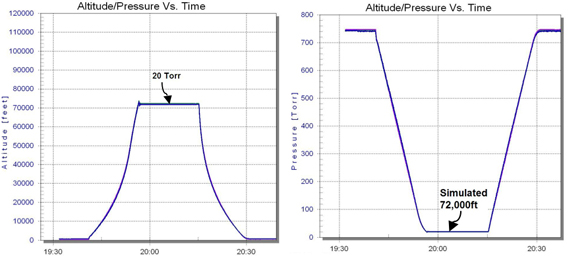

Example of a “Climb and Dive Profile” with our Advanced Altitude Control Package:

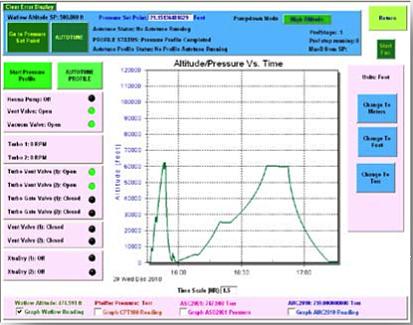

Figure 1 PC Touch Screen Package with simple “Climb & Dive”, and thermal profiling integrated with vacuum system.

Abbess offers a wide portfolio of vacuum systems to suit customer needs in addressing DOT and FAA ASTM test requirements, including with “Climb & Dive” and/or thermal profiling upgrade options. Simulated altitudes of up to 100,000 ft / 19miles / 30km (pressures ≥10-4 Torr) are feasible depending on the vacuum system ordered.

Profiling uses state-of-the art pressure and temp control techniques accessing full potential of temperature PID controllers/tuning. The Touch Screen GUI pressure profile offers a variety of display options: Torr, ft, m.

Both ‘simple’ & ‘complex’ profiling produces linear “Climb & Dive” in Torr. The “Climb & Dive” sample illustrations given here are of ‘simple’ profiling: The system operates in Torr; any values the operator inputs as feet are converted by the system for monitoring and control purposes. All ramps are linear in Torr, but non-linear in ft or meters (the average ft or m ramp rates achieved are those set by the operator).

Successfully address DOT and FAA ASTM test requirements in Abbess Instruments’ vacuum systems upgraded with a “Climb & Dive” PC Touch screen package.