With precise thermal and vacuum control, the Abbess Satellite Testing Vacuum (TVAC) System is ideal for ensuring the compliance of your product or satellite to sustain ultra-high and low atmospheric conditions. Abbess designs rugged equipment and practical systems for continuous and demanding analytical, manufacturing, and production use, with safety and long life in mind. Additionally, we offer various coating for solar simulation and other orbital variables.

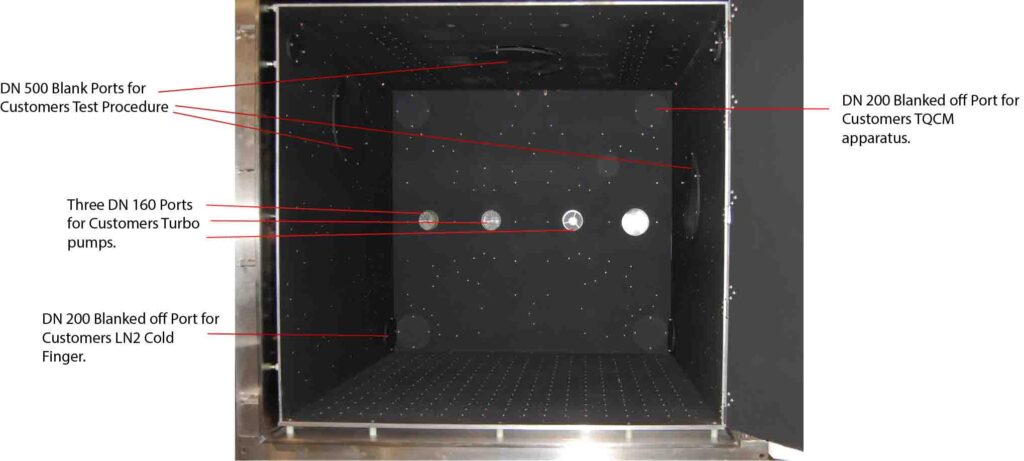

The chamber is fitted with an internal shroud which can be cooled down to LN2 temperatures or

heated up to 150degreeC with a minimum internal volume of 77in (H) x 72in (D) x 82in (W). The

chamber features three large DN500 ports, one located on top and one on each side. The TVAC system will sit on vibration isolators which will then be mounted to a optical table test setup.

Satellite Testing Vacuum System Features(TVAC):

- Vacuum Chamber (as shown above) – A Front Loading Stainless Steel Chamber with a right hinged Stainless Steel door. The interior of the chamber is Electropolished to attain high vacuum.

- Vacuum Pumping System – Through the use of any desired vacuum compatible pumping package. The package that was used on this device was three Leybold Turbo pumps and three Leybold dry roughing pumps to achieve a vacuum pressure of 10-7 Torr.

- Thermal Platen System – AeroGlaze® Coated Aluminum Thermal Plate with resistance cartridge heating elements and refrigeration media piping engaged in the under the surface of the thermal test platen.

- Thermal Shroud System – 5 sided AeroGlaze® coated Aluminum thermal plate with resistance cartridge heating elements and refrigeration media piping embeded in the back of each shroud. Thermocouple monitoring and temperature control via PID controller.

- Pressure Gauges/Pressure Transducers

- Control Valves

- Electromechanical Foreline Valve – Seperates the chamber and Turbo from the Roughing pump when venting the Chamber.

- Electromechanical Chamber Vent Valve – Gross venting valve.

- Electromechanical Chamber Purge Gas Vent Valve – Connected to the gas purge kit to allow dry nitrogen purge into the chamber.

- Gas Purge Kit – A set of preconfigured regulators, pressure relief valve, and gauges provide a controlled release of gas into the chamber.

Perform your test in-house for decades to come with this modifiable and upgradeable Satellite Testing Vacuum System(TVAC):

Benefits:

- Highly developed simulation and data collection touch screen system

- Custom user interface that is configured to custom specified equipment on your system including thermal controls

- Plot and save data, settings, and profiles

- Editable PID configuration with auto-tuning capabilities

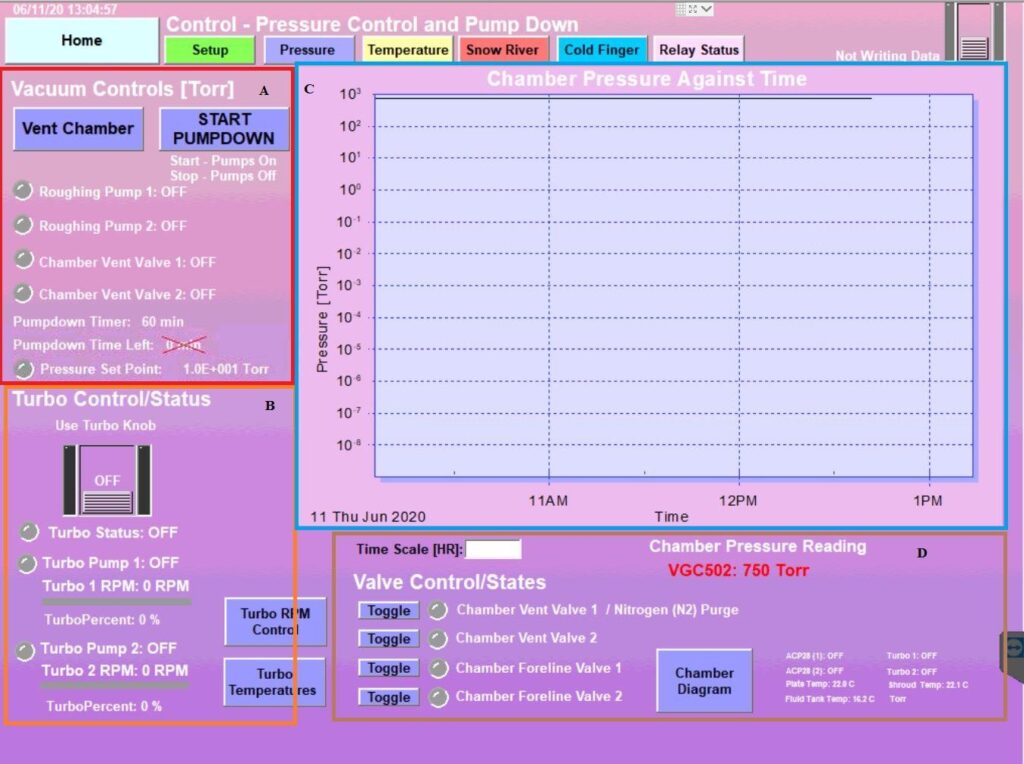

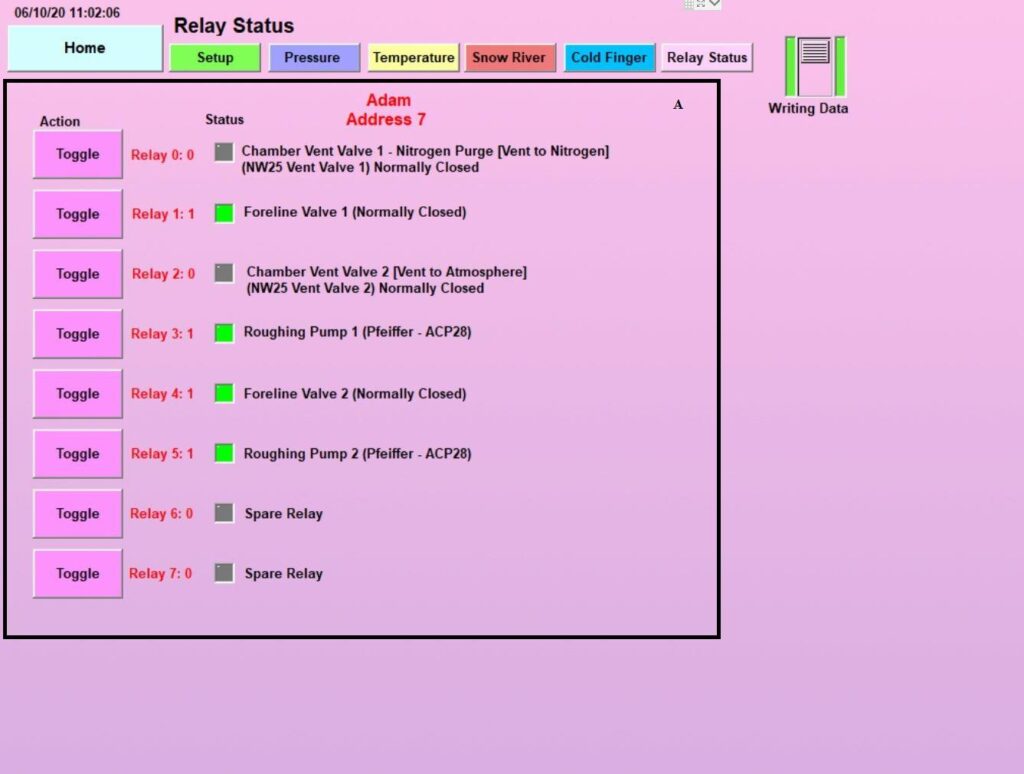

CUSTOM TOUCH SCREEN/PC VACUUM CYCLE CONTROLLER

Customized PC and Touch Screen User interface.

Allows controlled Start/Stop control of vacuum system, process, sequence, position, pressure and/or temperature monitoring and setpoint control.

Includes:

- Custom User Interface design, requires custom sequence

programing option - Custom NEMA/Work station

- Serial/USB PC interface

- Data Acquisition Interface

- Data Logging and batch records

- Many data output options

- Integration with pumps, valves, and other controllers

- With Vacuum pump relay options

PANEL PC,

- 15″ CAPACITIVE TOUCHSCREEN,

- WINDOWS 10

- Provides I/O for RS485, USB, and rs232 devices

- DUAL LAN

- MINIMUM 32GB 2.5″ SSD

- MINIMUM 4GB SO-DIMM DDR4 2666

A PC Touch Screen Vacuum Cycle Controller is a custom built system. Each Touch Screen Controller is programmed for the customer’s specific procedure.

Below is an example of what the GUI will look like: