The Abbess Instruments’ Vacuum Cold Trap is designed to precipitate vapors like water and other perceptible materials from gas streams developed in a vacuum processing or drying operation. Products or articles under vacuum may evolve vapors that can compromise the product or vacuum system components. The Cold Trap is used to filter the exiting gases of water, alcohol or other perceptible materials, in order to ensure that they do not damage or contaminate pumps or other items. Process gas is delivered to the chamber and exposed to -80°C temperature and trapped by freezing or cryo-plating the material on baffle plates in the trap. This trapped or frozen material is removed and disposed of by removing and cleaning the baffle plates in the trap.

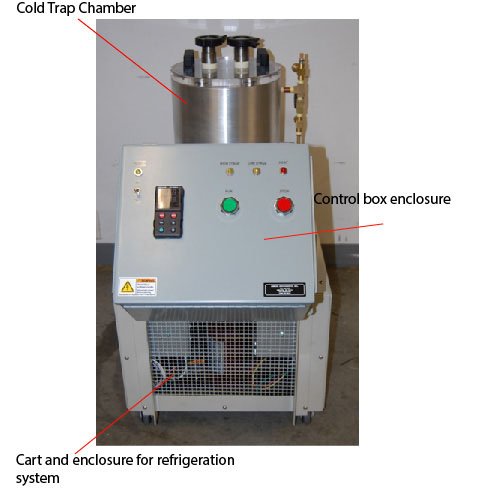

The Vacuum Cold Trap System consists of the following major components

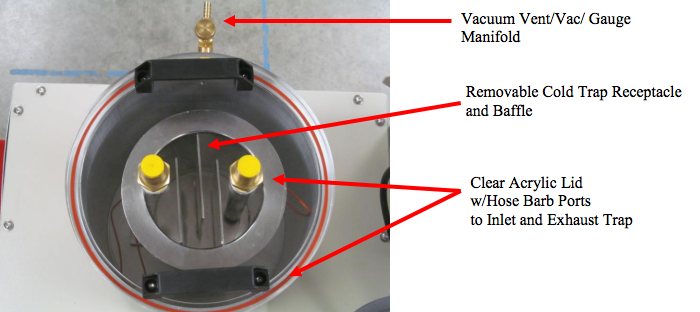

- 11” x 12” Cylinder Top Loading Vacuum Chamber

- Clear acrylic removable lid with gas stream inlet and outlet feed throughs

- Cold Trap

- Receptacle receiving assembly with coolant system and heating element for regenerative heating.

- Removable receptacle baffles – cooled by direct contact with the refrigerant lines.

- Electrical Control Enclosure

- Contains components necessary for controlling the cold trap process

- PID temperature controller – controlling the Cascade refrigerating systems

- Status Indicators – provide visual indication of system status.

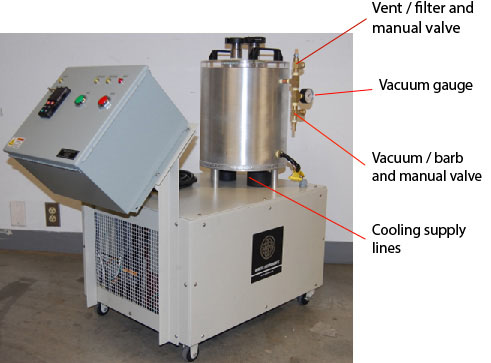

- Vacuum Pumping System

- Vacuum Pressure Gauge

- Analog vacuum pressure gauge reading in kPa and inHg.

- Control Valves

- Manual vent valve allows user to vent air into chamber at intervals during the trap process.

- The cooling system is designed to achieve and sustain set point temperatures to -80ºC within Cold Trap

- Process temperatures are controlled by circulation of refrigeration media (404a and 508b refrigerant) flowing through two integrated stages.

To get an accurate quote for the system you need fill out our RFQ or call today!